DUST EXTRACTION SYSTEMS – EFFICIENT AIR FILTRATION

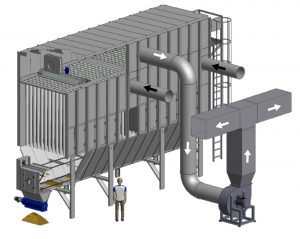

Reliable and Modular Dust Extraction Systems for Efficient Waste Extraction & Handling

Reliable and Modular Dust Extraction Systems for Efficient Waste Extraction & Handling

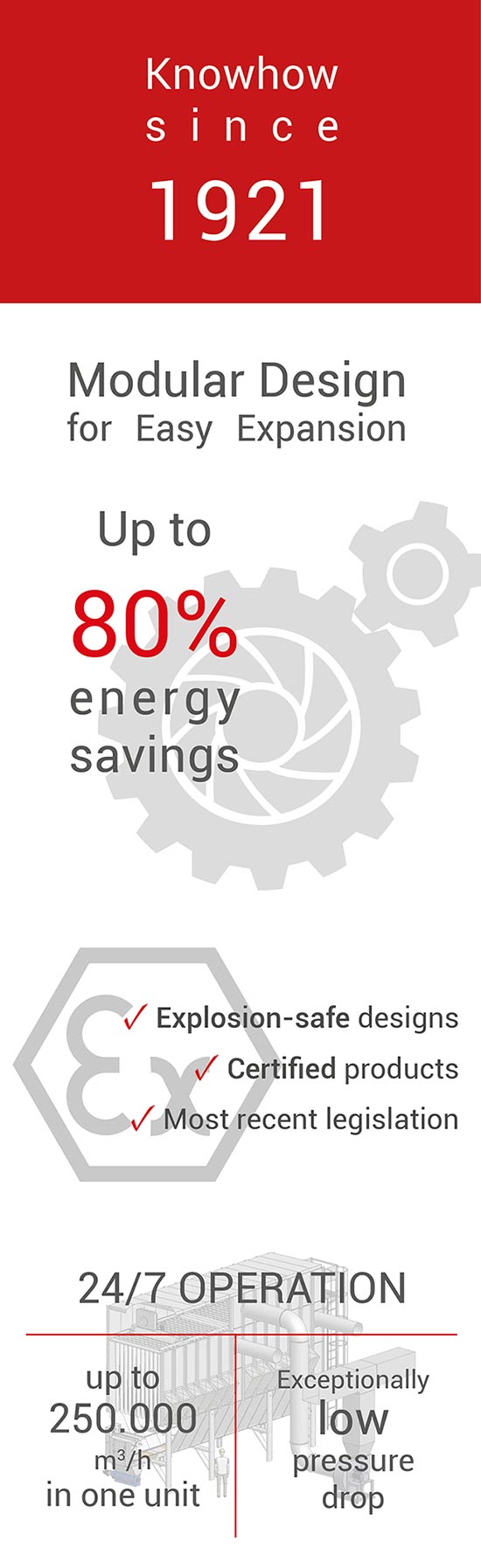

Having manufactured Dust Extraction Systems since 1921, we have built up a large know-how regarding dust extraction technology. Since then, we have supplied and supported modular dust collection filters for some of the largest manufacturing companies worldwide.

Customized Filtration Solutions for Your Needs

For a dust extraction system to operate optimally, it is important that it has been designed to the specific industry, working situation and environment taking into account operation frequency, material type, material loading, space and air quantity. At Moldow we design our dust extraction system with the specific working environment and situation in mind, which ensures delivery of the most reliable and efficient extractiona & air filtration system possible. This is not always the cheapest solution, however it is the best.

A Moldow dust extraction system is characterized by:

- high efficiency

- low energy consumption

- explosion-safe design.

This results in low operating costs without sacrificing operational efficiency and reliability.

Up to 80% Energy Savings with Moldow’s Technology

A Moldow Dust Collection System in combination with our ENSACO and highly efficient fans guaranties an energy optimized, reliable and durable dust extraction system that uses up to 80% less energy than traditional and competing systems.

All Moldow filters are modular in design which makes it possible to easily and economically customize each filter to the specific company’s requirements and facilities. It also future proofs the filter, as it can readily be extended if demands in air volume increase.

Explosion Safe Filter Design

Explosion safety is a key decision factor for manufacturing companies looking for a dust collection system – and with good reason. Our customers are always ensured systems with the highest safety level. At Moldow we manufacture our own certified products which enables us to always be at the forefront of current legislation. Learn more about our ATEX filters and system.

WE GUARANTEE

A HIGHLY EXPLOSION-SAFE

EXTRACTION SYSTEM

At Moldow we work hard every day to ensure that our dust collectors and all other products live up to the most recent and current legislation and regulations. By manufacturing our own certified products, we are able to always be at the forefront of current legislation. So not only are Moldow filters as energy efficient as possible, they also meet the highest requirements in safety.

EFFICIENT, RELIABLE EXTRACTION SYSTEMS

Here below you can have a detailed look at a small selection of our supplied extraction systems.

Two Efficient Dust Extraction Systems For VELUX

Due to increased production needs and a desire for more energy-efficient solutions, VELUX decided to invest in new dust extraction and replace two old filters with new ones. […]

Extraction Filtration System for Cardboard Producer

Moldow has designed, supplied and commissioned a new dust extraction and filtration system at a leading cardboard packaging producer in Poland. This marks the second successful collaboration […]

Dust Extraction System for High Quality Wooden Floors

Located in Denmark, the company produces ultra-high quality wood flooring solutions and other exclusive wood product solutions. Dinesen caters to the high-end market where quality is an absolute selling point. To exist within this market, the company requires the highest standards of […]

Safe, Efficient Dust Extraction Systems

Two dust extraction systems for efficient waste material extraction and air filtration at South American plywood manufacturer […]

Dust Extraction System for Cardboard Manufacturer

The customer was looking for a more cost-efficient waste material handling system, and in close cooperation with our distributor in Finland, PPT Pölynpoistotekniikka Oy, they found a solution with our […]

ATEX Dust Extraction System For Glass Fiber

We recently installed this ATEX dust extraction system for glass fiber dust at one of VELUX’s production sites in Denmark. In regards to the explosion hazard (ATEX), the explosion characteristics of the dust were unknown. Therefore, the dust was […]

Complete Production Line and Air Filtration System for Large Airlaid Manufacturer

Moldow A/S and Dan-Web Machinery A/S, two of the largest international suppliers within their respective fields, have in cooperation just finished the delivery of a complete production and air filtration system for the American Airlaid industry. The customer is one of the world’s largest manufacturers within airlaid – an industry responsible for producing […]

Extraction and filtration system of wood and cement

Air filtration specialist Moldow A/S has supplied three specially-designed, energy efficient dust extraction systems for acoustic panels manufacturer Troldtekt A/S’ 13,000 cubic meters production hall in Denmark. Troldtekt has opened a brand new […]

PROJECT STAGES – FULL DELIVERY & SUPPORT

Moldow assists you in every stage of the project:

Initial request • We or our local partner assess your needs and facilities to determine which dust extraction system will be the best based on your requirements and priorities.

Quotation • You receive a detailed quotation specifying the filter type, air quantities, price, delivery time etc. to give you a complete overview of the cost and time schedule of your project.

Production • After having received the order confirmation, we begin manufacturing the filter and equipment at our production facilities in Denmark which ensure the same high quality at all times.

Delivery & Installation • The system is shipped to your location, where our local partner takes care of assembly and installation or we can provide an experienced supervisor to ensure correct and trouble-free installation.

Commissioning & Training • Our local partner or the experienced supervisor can carry out the commissioning of the system and training of the staff that will be operating the system daily. The system is supplied with detailed instruction manuals for future reference and guidance.

Maintenance & Service • Periodic maintenance and inspection of your system is a necessity to ensure reliable and efficient operation. We or our local partner can assist you in this, and our service department is available 24/7/365.

CONTACT US

FAQ – LEARN MORE

Yes. Moldow designs systems that are fully-compliant with the ATEX directives. Our solutions for ATEX includes for example:

- Explosion relief

- Ex-certified rotary valves

- Ex-certified fans

- Spark detection and extinguishing

- Grounding and anti-static filter media

Moldow can ensure that the entire system, not just individual components, meets ATEX requirements.

We also supply dust extraction systems for non-ATEX applications.

Absolutely. Moldow specializes in custom-engineered dust extraction systems adapted to each customer’s layout, dust type, and production capacity. Our engineering capabilities include:

- Full 3D layout design

- Airflow calculations and system dimensioning

- Energy optimization

- Integration with existing machinery and production lines

- Turnkey delivery, installation, and commissioning

Moldow provides custom solutions both directly from our Danish or Polish engineering team and through qualified local partners in selected countries.

In these markets, our partners design the complete extraction system using Moldow products, components and know-how, ensuring the same high-quality standards and performance.

This gives customers worldwide access to Moldow’s expertise — either through our in-house engineering team or trusted regional specialists.

Yes. Moldow frequently modernizes, upgrades or expands existing systems by:

- Upgrading filter units or fans for higher capacity or efficiency

- Connecting new machines or production cells to the existing system

- Improving airflow with redesigned or optimized ducting.

One of the major advantages of Moldow’s baghouse filter technology is the modular construction.

This allows us to add additional filter modules to an existing unit to increase capacity — avoiding the need to invest in a completely new filter.

This makes system expansion cost-effective, fast to implement, and future-proof, especially for growing production facilities.

Yes. Moldow primarily serves the European market, with headquarters and production in Denmark and a dedicated Sales Office in Poland.

However, Moldow also delivers and supports specialized dust extraction systems worldwide — either directly to key industrial customers or through trained local partners and distributors.

Moldow currently works with local distributors in the following countries:

- United Kingdom & Ireland

- Czech Republic & Slovakia

- Slovenia & Croatia

- Germany

- Chile & Peru

- South Korea

Beyond these markets, Moldow supports selected international projects, especially those involving large-scale, complex, or ATEX-critical applications where our engineering expertise is essential.

For an updated overview, please see our list of distributors under Contacts, or reach out if you are interested in becoming a Moldow distributor in your local region.

A dust extraction system captures and removes dust from industrial processes and filters and clean the air, using a highly engineered airflow and filtration setup. The basic operation includes:

- Extracting dust at the machine source.

- Transporting dust-laden air through a balanced ducting system using extraction fans.

- Separating particles from the air stream in a Moldow filter unit.

- Returning clean air (recirculated or exhausted outside).

- Collecting dust in containers, silos, or compactors via direct discharge or a secondary transport system.

While the process may seem straightforward, every factory has unique dust types, machine layouts, air volumes and ATEX requirements.

This is where Moldow’s 50+ years of experience makes a significant difference, ensuring each system is designed for maximum efficiency, safety, and long-term reliability.

With proper maintenance and timely care, our experience is that Moldow extraction systems often operate 20-30 years or more.

This longevity is due to:

- Strong steel construction

- High-quality fans and motors

- Durable filter media

- Modular components for easy replacement

Many Moldow systems installed in the 1980s and 1990s are still in daily use.

A dust extraction system can range from a simple source-extraction setup to a large, fully integrated filtration and material-handling installation. Moldow designs systems for all scales and industries, always tailored to the dust type, production layout, and safety requirements.

A simple dust extraction solution typically includes:

- Extraction point(s) at machine(s)

- Ducting system

- Extraction fan

- Filter unit (cartridge or bag filter) with automatic cleaning

- Dust collection

- ATEX components if required

A larger or more advanced dust extraction system may include:

- Extraction point(s) at machine(s)

- Ducting system

- Extraction & transport fans

- Filter unit (cartridge or bag filter) with automatic cleaning

- ATEX components if required

- Rotary (airlock) valve

- Transport system after filter

- Container or silo for dust/material collection

Optional advanced system features include:

- Pre-separation before the filter

- Heat recovery or air recirculation systems

- Energy control system.

Moldow custom-designs every dust extraction system to match each factory’s exact needs. Every solution is adapted to the dust type, production process, safety regulations, airflow demand, and future capacity, ensuring long-term safe operation and maximum efficiency.

A baghouse filter is an industrial air filtration unit that removes dust and particles from an airflow using a series of filter bags made from durable fabric. As dust-laden air passes through the bags, the dust collects on the outside of the fabric while clean air flows through to the inside and is discharged or recirculated.

Baghouse filters are widely used in industries such as woodworking, metalworking, plastics, composites, paper, food processing, and general manufacturing, because they can handle large air volumes, heavy dust loads, and a wide range of particle sizes.

Key features of a baghouse filter include:

- High filtration efficiency for fine, medium, and coarse dust

- Automatic filter cleaning (typically via pulse-jet air cleaning or high-efficiency fan cleaning)

- Robust construction for long service life

- Flexible, modular design that can be expanded when production grows

- Compatibility with ATEX safety requirements when handling explosive dusts.

Moldow’s baghouse filters are known for their energy-optimized design, low pressure loss, and modular construction, which makes it easy to add extra filter modules as capacity requirements increase.

Choosing a dust extraction system depends on several critical factors:

- Type of dust (e.g. wood, metal, composite, explosive dust, fine dust)

- Airflow and extraction volume required

- Process layout (number of machines, duct lengths, airflow balance)

- Safety and compliance (ATEX classification, fire/explosion risk)

- Energy efficiency (intelligent control, fan technology, reuse)

- Future expansion (need to possible expand for higher production capacity in the future?)

Moldow systems are always custom-engineered to match your machinery, dust characteristics and energy targets – ensuring safe, efficient and compliant operation.

Our engineers and partners are here to help you with designing the right extraction systems, and our range of solutions includes everything to match your requirements and needs.

Moldow has spent more than 50 years optimizing products and system designs to achieve maximum energy efficiency in industrial dust extraction.

Our solutions combine advanced airflow engineering, intelligent control systems, and high-performance components to reduce energy consumption and operating costs.

Key features that make Moldow’s dust extraction systems highly energy-efficient include:

- Fans customized to each project’s exact operational parameters

- Optimized filter and housing construction designed to minimize pressure loss

- High-efficiency fan for filter cleaning, reducing compressed air use

- Intelligent frequency control for variable airflow

We can also include:

- ENSACO® energy-control system, providing an additional 40-80% energy savings through automatic adjustments of extraction volume according to needs

- Heat recovery systems

- Air recirculation to reduce heating costs

Together, these technologies ensure a significantly lower total cost of ownership, making Moldow’s dust extraction systems not only efficient but also sustainable and cost-effective for long-term industrial operation.

Moldow supplies:

- Central dust extraction systems

- High-capacity bag and cartridge filter systems

- Extraction systems for ATEX (explosive atmospheres)

- High-efficiency extraction systems

- Customized solutions for entire factories

- Energy-optimized retrofits for existing installations

All solutions are tailored to the customer’s process, dust type, and layout.

Moldow provides custom solutions both directly from our Danish or Polish engineering team and through qualified local partners in selected countries.

ATEX is essential because many industrial dusts – especially wood dust, metal dust, plastic dust, and fine organic particles – can be explosive under certain conditions.

With a dust extraction system designed according to the European ATEX directive ensure a proper risk assessment to account for:

- Proper venting and pressure relief

- Explosion isolation between filters and production lines

- Use of spark-proof fans, ducts, and electrical components

- Correct filter media and system grounding

Moldow designs and manufactures extraction systems according to the ATEX directives, ensuring maximum safety and full legal compliance for EU markets. We also offer various Ex-certified products to ensure maximum safety and control.

Read more about Moldow’s explosion safe extraction systems.