ATEX FILTERS – BAGHOUSE FILTERS FOR EXPLOSIVE ATMOSPHERES

ATEX Directive Compliant Baghouse Filters

Explosion in your dust extraction system can have a huge negative impact on your business, forcing you to shut down production for a long time. Therefore, filters and extraction systems that comply with the ATEX directive are crucial. Anything that burns has potential to explode, and the smaller the particle size, the higher the explosiveness. So:

Explosion in your dust extraction system can have a huge negative impact on your business, forcing you to shut down production for a long time. Therefore, filters and extraction systems that comply with the ATEX directive are crucial. Anything that burns has potential to explode, and the smaller the particle size, the higher the explosiveness. So:

- determining the explosiveness of your dust and

- choosing a correctly designed system with the right equipment

is crucial and your best insurance as you minimize the risk of explosion immensely.

At Moldow we work hard every day to ensure that our dust collectors and all other products live up to the most recent and current legislation and regulations. By manufacturing our own certified products, we are able to always be at the forefront of current legislation. So not only are Moldow’s dust collectors as energy efficient as possible, they also meet the highest requirements in safety.

Moldow’s ATEX filters are designed to handle explosive atmospheres.

What does that mean?

- They provide protection against explosions by ensuring that the filter has no own ignition sources.

- They are equipped with correctly calculated and designed explosion venting to relief an explosion in a safe way.

- They can include spark detection and extinguishing systems to prevent external ignition sources.

Correct Design of ATEX Filter with Explosion Relief

In the unlikely event that dust should be ignited due to an external ignition source and a deflagration occur, the filters’ explosion relief must ensure that pressure is relieved in a safe way.

This will leave the dust collector structurally intact and not cause creation of projectiles which can harm personnel and property.

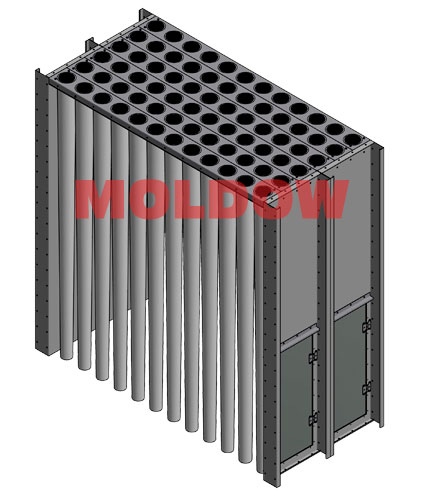

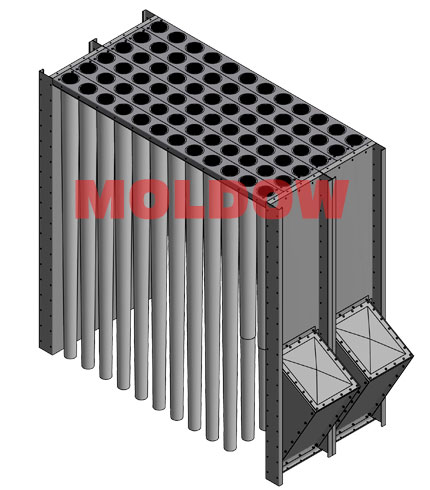

We offer two types of explosion relief for our MHL filter: self-manufactured, type-approved explosion relief doors and our very popular explosion relief panels with safe upwards relief. Our other ATEX baghouse filters are designed with our self-manufactured, type-approved explosion relief doors.

FULL-SCALE EXPLOSION-TESTED BAGHOUSE FILTERS

Proper design and testing of construction & explosion relief

Proper design and testing of construction & explosion relief

Moldow’s filters have been full-scale explosion tested by a Notified Body, which is why we can guarantee that our baghouse filters meet the highest safety requirements, and that a possible explosion will be relieved safely.

If a dust extraction system is designed correctly preventing the equipment’s own ignition sources, and if the system includes protection against external ignition sources, the explosion risk is minimal but still present. That is why Moldow filters are equipped with explosion venting.

Should an explosion occur, the explosion venting prevents a demolition of the filter and an uncontrolled explosion relief – when the explosion venting area has been calculated correctly.

– In this case, “calculated correctly” is the important thing. Our calculations for Moldow filters have been validated in a full-scale explosion test by a European Notified Body, which is why we can guarantee a possible explosion will be relieved safely. If the explosion venting area does not match the strength of the filter casing, there is a big risk of an uncontrolled explosion despite the explosion venting, Safety & QA Manager at Moldow, Carsten Hembo, explains.

At Moldow we offer two types of explosion venting. Our own type-approved EX-DOORS and our explosion panels with upwards explosion relief.

Further, systems including rotary valve can be equipped with integrated pressure sensor to perform interlock based shutdown of the complete extraction system in the case of pressure increase due to a deflagration within the filter.

To ensure the high efficiency of the whole system, Moldow also offers a full range of fans that are likewise designed for ATEX.

Want to know more?

Contact us by email or filling out the contact form to learn more about our ATEX and NFPA compliant filters and products.

CONTACT FORM

READ MORE ABOUT ATEX FILTERS

Extraction System Design According to ATEX Directive

Explosion in a dust extraction system can have a huge negative impact on your business, forcing you to shut down production for a long time.

Safe, Efficient Dust Extraction Systems

Two dust extraction systems for efficient waste material extraction and air filtration at South American plywood manufacturer […]

Dust Extraction System For Furniture Manufacturer

Moldow Baghouse Filter and Fans for Efficient Woodwaste Extraction & Filtration. Installation and commissioning of an all-embracing dust extraction system for Dams International, a leading […]