DUST EXTRACTION & FILTRATION

BAGHOUSE FILTERS

We manufacture baghouse filters used for the extraction and filtration of dust and waste created by the production processes within the woodworking, paper, cardboard, mineral wool and airlaid industries. Our products and systems have been developed based on deep industry knowhow since 1921.

Low operating costs · reliable air filtration · improved working conditions · high production efficiency · compliance with most recent legislation

WET PAINT & POWDER COATING LINES

AUTOMATIC PAINTING LINES

We design and produce complete, automated lines for wet painting and powder coating of metal, plastic and wood items. A long list of satisfied customers proves that our knowhow and skilled in-house engineering department ensures the right painting solution every time.

Technically sound solutions · 100% customized · high operational reliability · confidence-building project management · on-schedule deliveries

ATEX & LEGISLATION

SAFETY AS A TOP PRIORITY

Our products and systems always live up to the most current legislation and regulations.

By manufacturing our own certified products, we are able to be at the forefront of legislation and supply systems that meet the highest safety requirements.

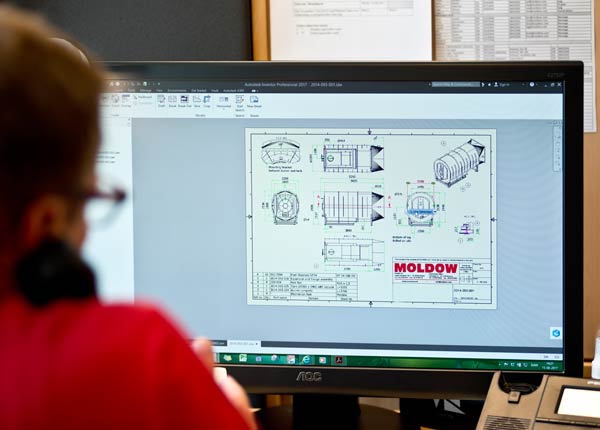

IN-HOUSE ENGINEERING

IN-HOUSE ENGINEERING

Engineering is the foundation on which our company is built.

Our in-house engineering department with deep industry knowledge and experience in dimensioning and designing systems for extraction, filtration and painting ensures that our customers always get the best and most reliable solution.

OWN SERVICE DEPARTMENT

OWN SERVICE DEPARTMENT

Our service department provides around the clock expert assistance because we understand how important it is that your system always runs smoothly.

Our supervisors and service technicians are experts in our products and systems. They handle everything from installation and commissioning to service, maintenance, trouble-shooting and repairs.

SUSTAINABILITY

SUSTAINABILITY

The increasing demands for sustainable and environmentally friendly production means that focus must be on highly optimized production systems.

All Moldow systems have been developed and optimized over the last 50 years with extreme focus on the environment and sustainability.

60 YEARS IN BUSINESS

+60 YEARS IN BUSINESS

We are the 2nd and 3rd generation of a family-founded and -owned company who take pride in supplying our customers with the best solution every time.

We are big enough to take on most tasks, but small enough to still cherish establishing a close personal relationship with our customers.

Being a merger of Jørgen Hansens Maskinfabrik from 1960 and H. Moldow founded in 1921, one might say that we are approaching 100 years of experience.

INDUSTRIAL FANS

CENTRIFUGAL & AXIAL FANS

Until October 2016, Moldow also sold fans for various industrial applications, but the sale of those Moldow-manufactured fans has been moved to Moldow’s sister company BarkerBille A/S.

The cooperation between Moldow and BarkerBille is close, and the fans are the same high quality as always.

If you are buying a Moldow Dust Extraction System or Painting Line, fans are included in the project as previously, so you will not have to go through BarkerBille.

CONTACT US

CONTACT FORM

Fill out this contact form and we will get back to you as soon as possible.

“Thanks to a very professional and focused project management, Moldow has succeeded in meeting our required time schedule and installed and commissioned our new paint line to our full satisfaction. Our impression of the project has been very positive with an excellent cooperation from sales to commissioning including high technical quality and availability”.

“We have focused on choosing the very best solutions for our new oak floor factory. Reliablity and uptime have been very crucial to our selection of equipment suppliers, and this is why we have chosen Moldow’s extraction system”.

“The design of our filters contribute to the large savings compared to other types of filters on the market, as the air velocity in the filter is lower, the pressure loss is minimal, and the bag cleaning is very efficient. The return air to the machines and the heat exchanger is also an important factor when designing an energy optimized system as the extracted air and heat is recovered and sent back to the machines and production facilities”.

“We had a very tight timeline to meet, but Moldow approached our project in a professional manner the like of which I have never encountered before. This to me was exceptional, and when I tell the story of Electron’s plant journey to visitors, it is greeted with semi disbelief. Not only did Moldow deliver on time but the support we have had since handover has been unbelievable and the enthusiasm to resolve our issues has been exemplary”.

“We see a lot of companies who are not getting the safety level that they think. It requires in-dept knowledge of how all the components in a system work together, how the material is processed and handled to ensure a truly safe system that lives up to applicable standards.”

NEWS

Meet us at DREMA

From September 9 to 12 you can meet us at Targi DREMA | […]

Strengthening Local Presence And Service for The Swedish Market

Moldow Welcomes SA Improvement AB as Official Partner in Sweden

“We’re pleased to announce SA Improvement […]

New Office in Denmark

Moldow Opens New Office In Svendborg, Denmark

We’re pleased to announce the opening of a new […]

New Energy Savings Project: Largest ENSACO® Installation in Poland to Date

Energy Savings on Dust Extraction at MARDOM

Moldow has just launched a large-scale ENSACO® installation at […]

WHO IS MOLDOW?

Thanks to the know-how and experience gained after manufacturing and developing our products since 1921, Moldow is one of the market leaders in designing and manufacturing:

- Dust extraction and collection systems for the woodworking, corrugated cardboard, paper and fiber industries.

- Painting lines for industrial coating of metal, plastic and wood items with either wet paint or powder coating.

Quality is key – all the systems are designed to be as reliable and energy efficient as possible. This is often not the cheapest solution, but it is the best.

Our head office and production facilities are located in Holsted, Denmark, from where our products are exported worldwide. Moldow is also represented in Poland and through distributors worldwide.