PAINTING LINES FOR WET PAINT AND POWDER COATING

Trusted Painting Lines Manufacturer

With more than 50 years of experience, Moldow is one of the leading international suppliers of painting lines for industrial painting of plastic, metal or wood items. Taking care of everything from design and manufacturing to installation and commissioning, your company is guaranteed a secure, efficient phase from first idea until final hand-over.

A Moldow Painting Line is designed to operate highly efficiently and reliably for many years and customized for each project by our in-house engineering staff. Our ability to customize our solutions for each project enables us to supply everything from manual lines to fully-automated lines. Read more below.

Moldow’s industrial wet painting & powder coating lines are supplied as a complete delivery including all the necessary process zones:

- Pretreatment

- Paint application

- Flash-off

- Drying and Curing

- Cooling

- Load and unload

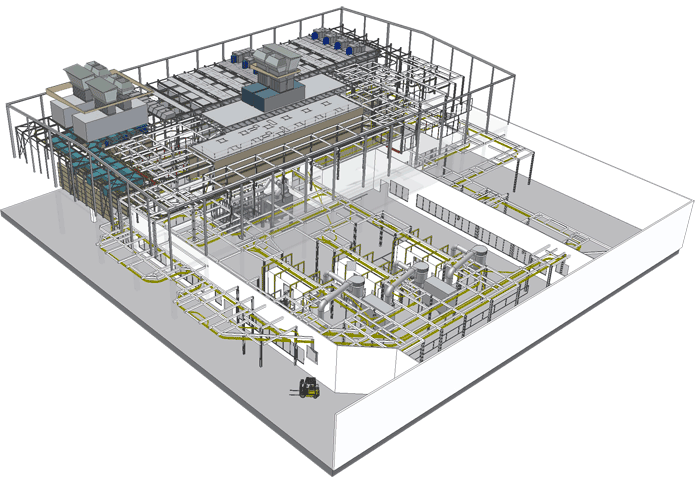

Furthermore, control rooms and systems, paint kitchen, sludge handling, conveyor systems and fully balanced ventilation system with accurate temperature and humidity control can be included.

Customized Painting Lines that Meet Your Requirements

For us, customer satisfaction is the most important factor. Therefore, experienced engineers and technicians follow the project from first idea to the final handover of the line. This ensures compliance with customer requirements, high quality of the final delivery and reliable information and guidance.

Given that a turnkey painting system includes equipment outside our range of products, cooperation with the best suppliers of e.g. robots, spray equipment and sludge handling systems ensures the high quality of the whole painting line.

Companies that benefit from having a Moldow painting line includes manufactures of:

CONTACT FORM

MEET US AT

DETAILED PROJECT DESCRIPTIONS

Market-leading Low Scrap Painting Line for Automotive Parts

The complete plant layout for this automotive plastic painting line was designed in close cooperation between Moldow and Farplas to optimize workflow and minimize footprint […]

Painting Line for Tier 1 Automotive Parts

The plastic painting line that we have supplied for Polyplastics in India is used to paint the front grills and other moulded plastic parts for Suzuki, Renault and […]

Automated Plastic Painting Line in Sweden

High quality painting of automotive plastic parts and 25% energy savings at Plastal in Simrishamn, Sweden. In early 2018, the Swedish company Plastal AB, […]

State-of-the-Art Powder Coating with Advanced Robot Application

High quality powder coating with frequent color changes at Bramidan A/S’ new painting line in Denmark. As part of a larger investment plan, they decided to replace their existing, manual wet paint line with a […]

Painting Line for Plastic Automotive Trim Parts

High quality plastic painting line supplied for automotive trim part is designed to minimize contamination between the individual zones to achieve the necessary high-end product quality […]

Manual Painting Line For 38 M Long Wind Turbine Towers

Moldow has delivered a painting line including sand blasting booth and two paint cabins for Titan Wind Energy in Esbjerg, Denmark – a company that produces […]

Highly Flexible Powder Coating Line for Steel and Aluminium Items

This automated painting line for powder coating of signs and boards was designed by Moldow to meet the requirements of exceptional flexibility. This was a special […]

Two-leveled Powder Coating Line for Forklifts

With the ambition of reaching the overall environmental, quality and capacity targets of Toyota Material Handling Europe, Moldow supplied this automated powder coating line […]

Maximum Energy optimizations and minimal carbon footprint – to benefit you and our environment

Energy optimizations and sustainability is crucial and play a fundamental role in every plant design.

For us, this is not something new. For more than 50 years, we have incorporated energy saving solutions in our designs.

We know how to optimized and customize each layout and design to fit your requirements in terms of efficiency, running costs, technology and footprint.

Your needs as our customer are the foundation for every project

Based on your needs combined with our know-how, we find the right painting line solution for you.

With more than 50 years of experience and a competent staff of engineers and project managers, we are capable of supplying turnkey installations to comply with the specific requirements of each industry and your company.

We got your back all the way through a project – from the first brief to the final hand-over to the after-sales services. This will ensure a successful and satisfying project phase and solution.

Have a look at other painting line projects where we have ensured just the right solution for our customers.

PAINTING LINE DESIGN ACCORDING TO SPECIFIC NEEDS

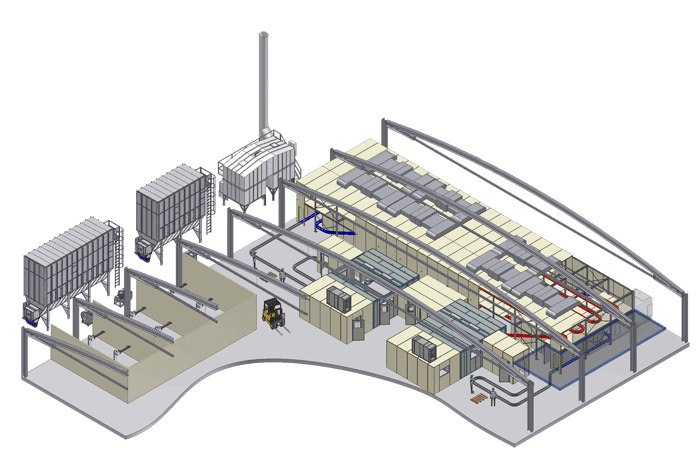

The design of a painting line can range from being fully manual with both the transportation from one process to another and the paint application being handled manually to a semiautomatic or full automatic painting line, where the transportation and/or application is automated.

Manual Painting Lines

A manual painting line is suitable when flexibility is crucial, e.g. when painting large, complex items or items of varying sizes and shapes. With many color changes, a manual paint application can also be the best solution.

The painting lines are designed with the required boxes and cabines for cleaning, pre-treatment, application and curing, and all processes are separated and ventilated according to needs.

Automatic Painting Lines

If there is a need for a painting line with large capacity, a full-automatic painting line is the best way to ensure an efficient and reliable painting process. In other situations, a semi-automatic line with manual handling of some of the processes can be the best solution.

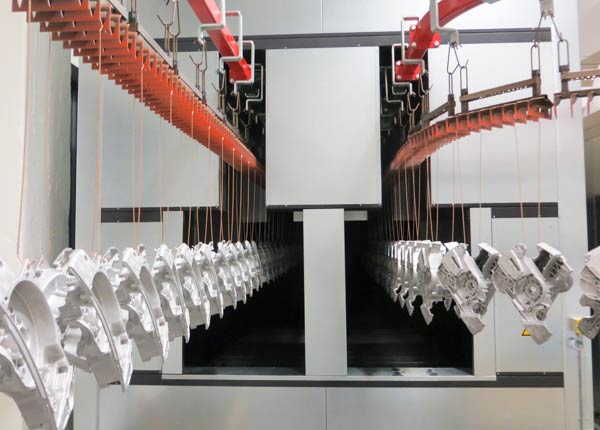

In a fully automatic painting plant, the items are transported automatically from one process zone to another either on overhead conveyor, floor-mounted conveyor, power and free-conveyor or roller conveyor, and the paint application is performed by use of robots.

The complexity of an automatic painting line varies a lot depending on item type, capacity needs and surface treatment. Moldow’s many years of experience makes us specialists in designing these complex painting lines, where the design and composition of the different process zones ensure a final result that meets expectations.

OTHER PRODUCTS

Moldow designs, manufactures and supplies complete painting lines for wet paint and powder coating of metal, plastic and wooden items. This means that in our delivery, a wide range of services, systems and products are included including among others:

- Pretreatment booths

- Paint booths

- Flash-off zones

- Drying and curing ovens

- Ventilation systems

- Loading/unloading systems

- Paint kitchens

- Sludge handling systems

- Control systems

Given that a turnkey painting system includes equipment outside Moldow’s range of products, cooperation agreements with the best suppliers of e.g. robots, spray equipment and conveyor systems ensures the high quality of the whole painting line.