SPRAY PAINT BOOTHS

Paint Booths for Wet Paint and Powder Coating

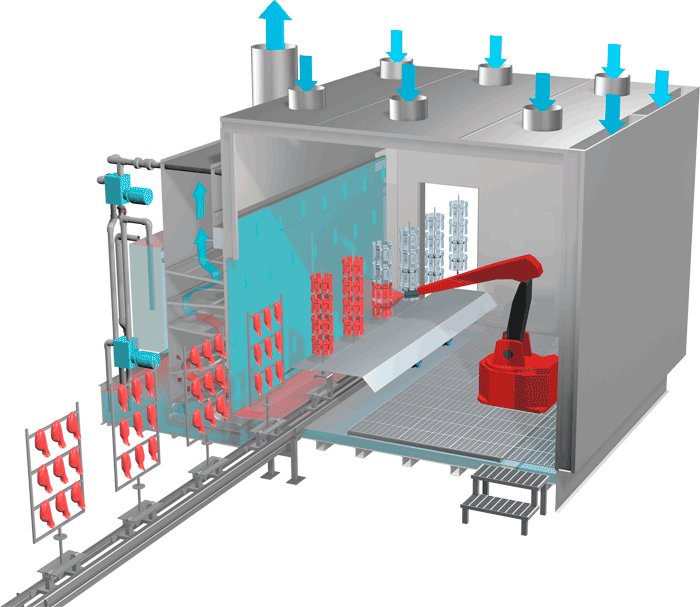

The application process in a painting line varies depending on the capacity requirements, item type and size and painting used. The essential is that the excess paint is captured and removed and the air is cleaned. For this purpose, a paint booth is used.

Based on your requirements and facilities, we design the right application process solution and painting booth for you.

With more than 50 years of experience in designing all types of spray paint booths, we can supply a solution that meets all requirements to efficiency, capacity and low energy use. At the same time, all paint booths meet the highest requirements to fire safety, ATEX, work environment and machine safety.

Spray Paint Booths for every Application

We have previously supplied everything from spray booths for 38 m long items, combined spray and drying booths, built-in water wall spray booths to simple dry filtration booths.

Having an in-house engineering department, we custom-design a solution for you as we have done for so many else, like:

- BT/Toyota who has a painting line with three powder coating spray booths where the items are directed automatically to the booth with the item-specified color.

- Titan who paints 38 m long wind turbine towers in two large spray booth halls. Panels along the sides and down draft system take care of the extraction and filtration of the paint.

See more project highlights here.

Learn more about Moldow’s wet spray booth with “no pump technology” and market-leading collection of overspray of more than 99% below.

CONTACT FORM

WET SPRAY BOOTHS – PAINTING BOOTHS FOR MANUAL OR AUTOMATIC WET PAINT APPLICATION

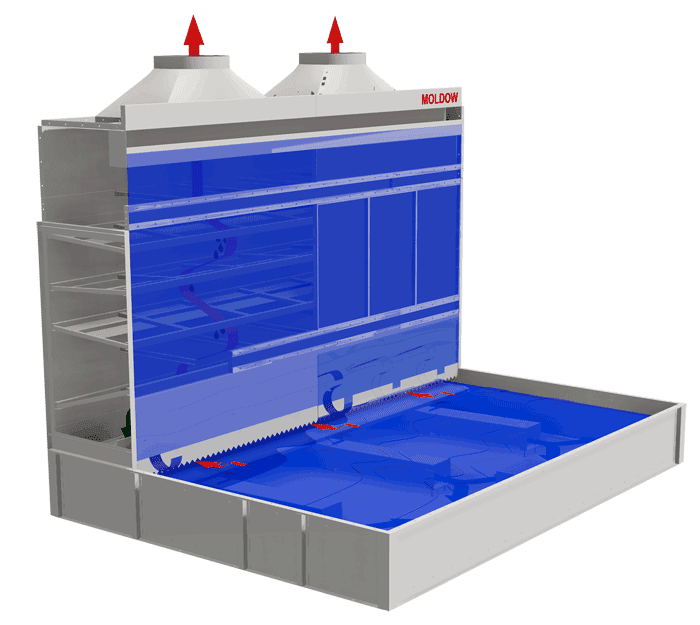

Painting booths are either with wet or dry filtration. Wet spray booths, ie. Water wall booths, are used widely in fully-automatic painting lines, where efficient application and collection of overspray is essential.

The Moldow “No-Pump” wet filtration booths perform market-leading overspray separation of more than 99% in a wide range of both solvent and water based painting processes.

The combination of strong air management and the water-sprinkled spray walls ensure that all the overspray is caught so the operators can work safely.

The air, including the overspray, is extracted from the lower part of the booth, where the mix of air and overspray is absorbed by the water when meeting the water surface. To achieve the unrivalled collection of overspray in a Moldow spray booth, the absorption of overspray is intensified by the powerful water cyclone inside the washing tower. Inside the washing tower, the water with the bound overspray is separated through a labyrinth of deflectors, separating the water from the air allowing the air to escape through the extraction system.

The paint-filled water from the washing tower is led to the floor reservoir where coagulants are added. By adding coagulants, the paint particles are released from the water and transformed into non-sticky flocculants.

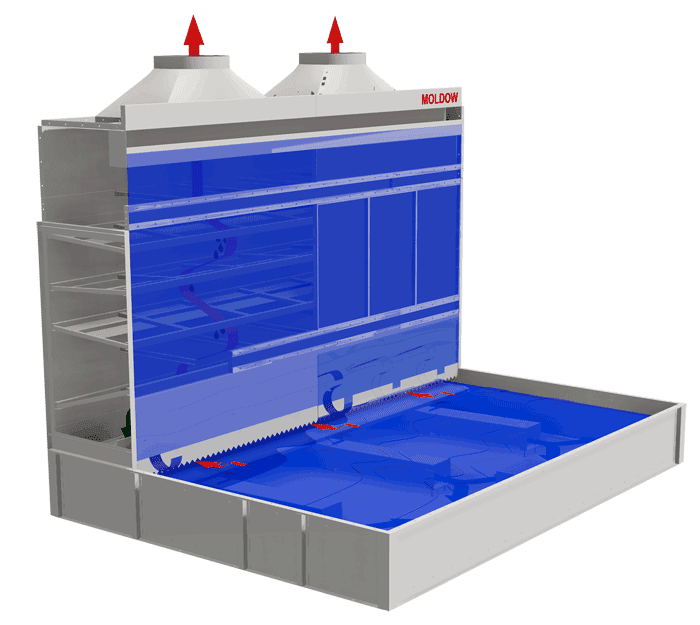

HEAVY DUTY TYPE

The Moldow spray booths can be supplied as Heavy Duty (HD) types upon request.

The HD system provides excellent maintenance and service access behind the booth during operation. The HD system is thus an advantage when the system capacity is high, or when minimal off-time for service and maintenance is required.

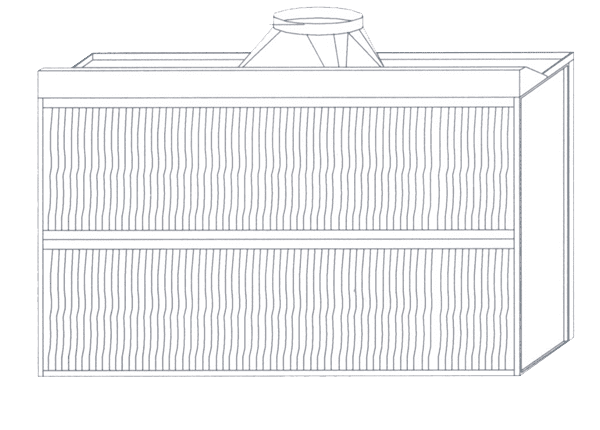

DRY FILTRATION SPRAY BOOTHS

Dry filtration spray booths are more simple than wet spray booths and require less maintenance.

Moldow’s dry filter booths are equipped with easily replacable Andreae® filters, which are the most efficient dry filters on the market.

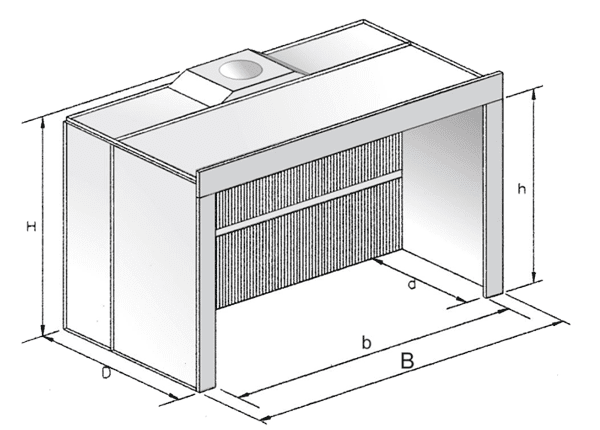

The correct depth, approved light fittings and an efficient industrial fan ensure optimal working conditions for the operator and create ideal conditions for a high finish.

Moldow supplies special dimensions if required.