PAINTING LINES – PAINT SHOPS FOR PLASTIC ITEMS

Plastic Paint Shop with high RFT ratio

It requires a high quality painting line to achieve the best finish when painting plastic components.

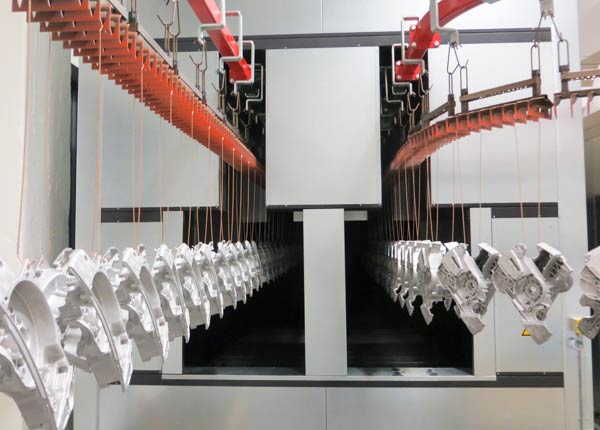

Through the years, Moldow has built an extensive knowledge about painting of plastic components and synthetic materials, as for instance mobile phones, plastic items for the automotive industry, casings for TVs and lampshades.

A high quality pre-treatment, dust free areas and accurate control of the air currents are highly important to ensure a high quality product finish that lives up to expectations.

A Moldow plastic paint shop ensures:

- Superior results

- Continuous operation

- Energy optimization

- High reliability

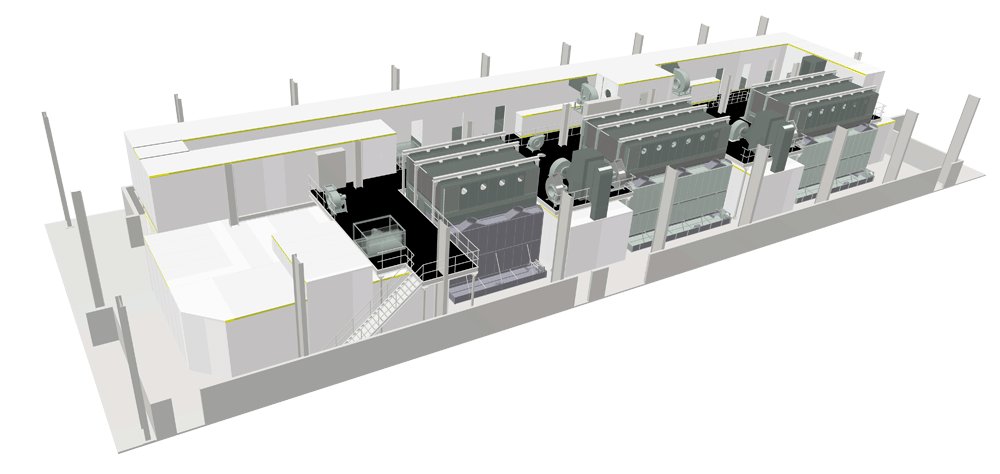

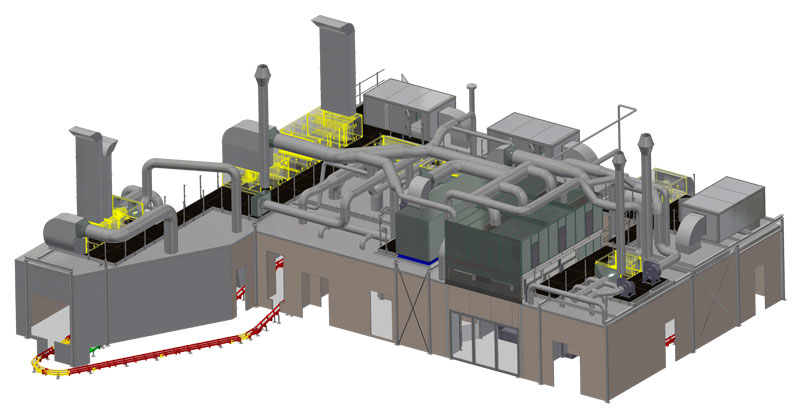

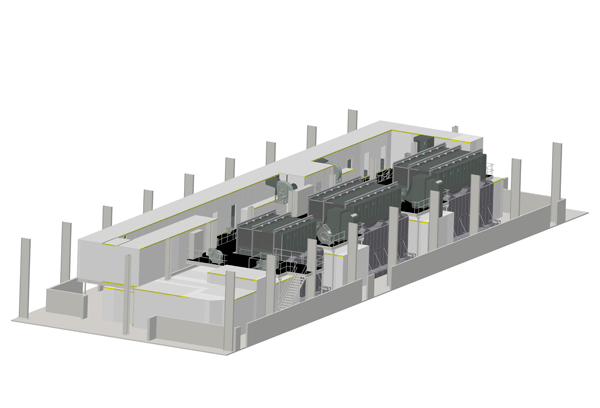

A typical Moldow paint finishing installation is supplied with all necessary process zones: Load/off-load, cleaning, pretreatment, spray booths, flash-off, curing oven and cooling zone.

Customized Paint Shops for Automotive Plastic Parts

Paint shops for plastic items are designed to minimize contamination between the individual zones to achieve the necessary high-end product quality. The minimum contamination between the process zones is ensured by a designed and accurately controlled down-draft ventilation system, including individual control of extraction and inlet airflows.

A plastic paint shop ensures compliance with customer requirements, high quality of the final delivery and reliable information and guidance.

Given that a turnkey painting system includes equipment outside our range of products, cooperation with the best suppliers of e.g. robots, spray equipment and sludge handling systems ensures the high quality of the whole painting line.

CONTACT FORM

DETAILED PROJECT DESCRIPTIONS

Automated Plastic Painting Line in Sweden

High quality painting of automotive plastic parts and 25% energy savings at Plastal in Simrishamn, Sweden. In early 2018, the Swedish company Plastal AB, […]

Automotive Exterior Parts Painting Line in India

LARGE, TWO STOREY AUTOMOTIVE PLASTIC PAINT SHOP Being designed for front grills and moulded exterior parts, the plastic paint shop will have a total footprint of […]

Painting Line for Plastic Automotive Trim Parts

High quality plastic painting line supplied for automotive trim part is designed to minimize contamination between the individual zones to achieve the necessary high-end product quality […]