POWDER COATING LINES

Powder Coating Lines with High Efficiency

Efficient utilization of the powder, quick color change, good adherence and efficient curing plus a high level of automation are the keywords when it comes to powder coating lines. In addition, Moldow’s powder coating lines comply with environmental requirements and provide safety for the operators.

To achieve the highest product finish when using powder coating, the pre-treatment is essential. Moldow have the necessary experience to design the right solution every time, whether it is a complex 8-step pre-treatment process or a correctly ventilated area for manual degreasing with a cloth.

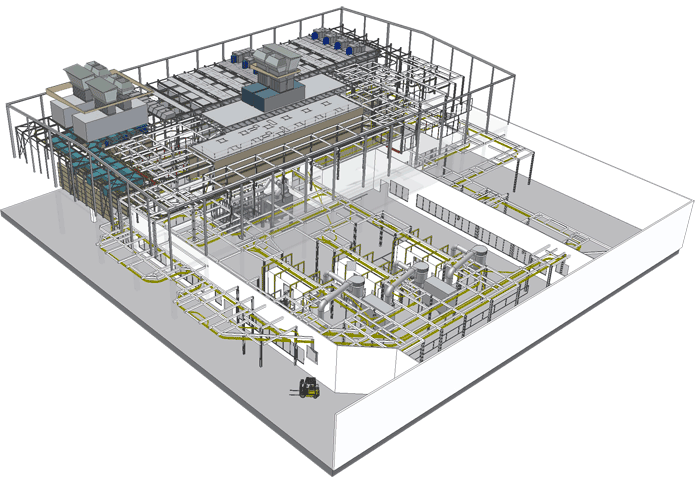

In addition to the complete pre-treatment process, Moldow powder coating lines are designed and supplied with all other necessary process zones, as for instance load and unload stations, cleaning, spray booths, drying and curing ovens, cooling zones and the essential ventilation system.

Metal Powder Coating Lines Require Effective Project Management

Large and complex automatic powder coating lines require effective project management that is capable of coordinating the integration of all the equipment at the agreed deadline. With our more than 50 years of experience and a large number of fully automatic coating lines delivered worldwide, we find the right solution for your company that provides flexibility and safety all the way.

State-of-the-art Powder Coating Line with Advanced Robot Powder Application

This pre-treatment and powder coating line we designed and installed for coating of steel parts. Find the full project description here, or watch the video:

CONTACT FORM

DETAILED PROJECT DESCRIPTIONS

State-of-the-Art Powder Coating with Advanced Robot Application

High quality powder coating with frequent color changes at Bramidan A/S’ new painting line in Denmark. As part of a larger investment plan, they decided to replace their existing, manual wet paint line with a […]

Two-leveled Powder Coating Line for Forklifts

With the ambition of reaching the overall environmental, quality and capacity targets of Toyota Material Handling Europe, Moldow supplied this automated powder coating line […]

Highly Flexible Powder Coating Line for Steel and Aluminium Items

This automated painting line for powder coating of signs and boards was designed by Moldow to meet the requirements of exceptional flexibility. This was a special […]