DUST EXTRACTION SYSTEMS – EFFICIENT AIR FILTRATION

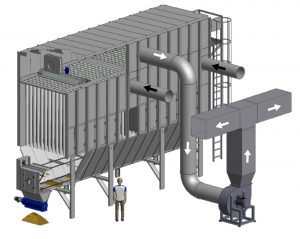

Reliable and Modular Dust Extraction Systems for Efficient Waste Extraction & Handling

Reliable and Modular Dust Extraction Systems for Efficient Waste Extraction & Handling

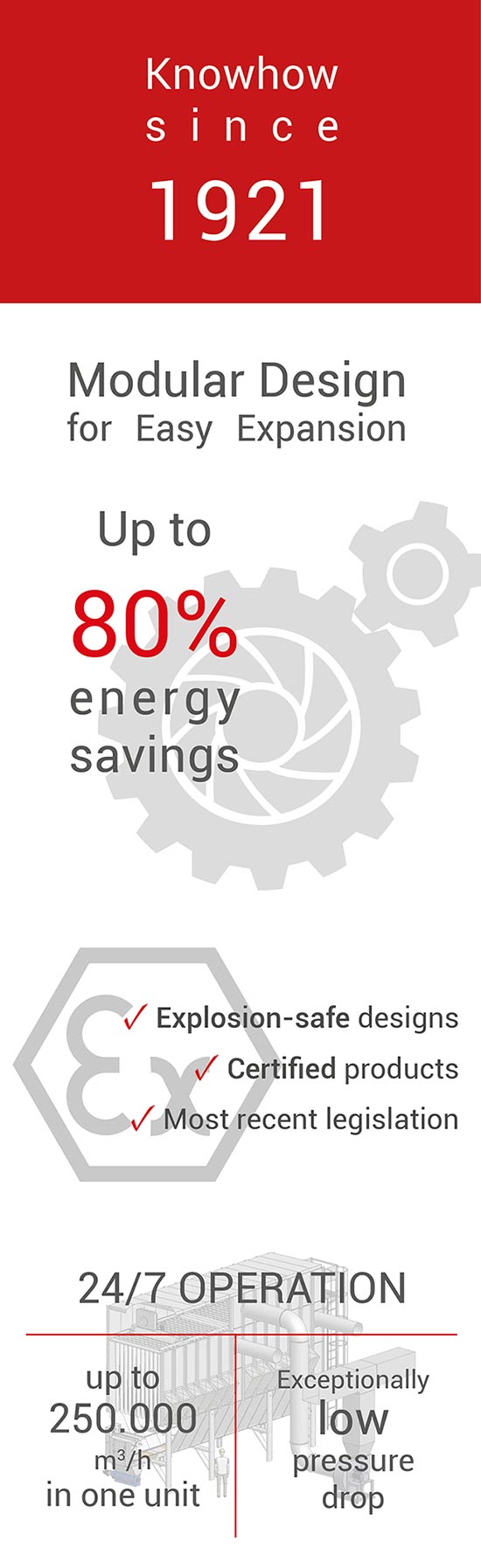

Having manufactured Dust Extraction Systems since 1921, we have built up a large know-how regarding dust extraction technology. Since then, we have supplied and supported modular dust collection filters for some of the largest manufacturing companies worldwide.

Customized Filtration Solutions for Your Needs

For a dust extraction system to operate optimally, it is important that it has been designed to the specific industry, working situation and environment taking into account operation frequency, material type, material loading, space and air quantity. At Moldow we design our dust extraction system with the specific working environment and situation in mind, which ensures delivery of the most reliable and efficient extractiona & air filtration system possible. This is not always the cheapest solution, however it is the best.

A Moldow dust extraction system is characterized by:

- high efficiency

- low energy consumption

- explosion-safe design.

This results in low operating costs without sacrificing operational efficiency and reliability.

Up to 80% Energy Savings with Moldow’s Technology

A Moldow Dust Collection System in combination with our ENSACO and highly efficient fans guaranties an energy optimized, reliable and durable dust extraction system that uses up to 80% less energy than traditional and competing systems.

All Moldow filters are modular in design which makes it possible to easily and economically customize each filter to the specific company’s requirements and facilities. It also future proofs the filter, as it can readily be extended if demands in air volume increase.

Explosion Safe Filter Design

Explosion safety is a key decision factor for manufacturing companies looking for a dust collection system – and with good reason. Our customers are always ensured systems with the highest safety level. At Moldow we manufacture our own certified products which enables us to always be at the forefront of current legislation. Learn more about our ATEX filters and system.

WE GUARANTEE

A HIGHLY EXPLOSION-SAFE

EXTRACTION SYSTEM

At Moldow we work hard every day to ensure that our dust collectors and all other products live up to the most recent and current legislation and regulations. By manufacturing our own certified products, we are able to always be at the forefront of current legislation. So not only are Moldow filters as energy efficient as possible, they also meet the highest requirements in safety.

PROJECT STAGES – FULL DELIVERY & SUPPORT

Moldow assists you in every stage of the project:

Initial request • We assess your needs and facilities to determine which dust extraction system will be the best based on your requirements and priorities.

Quotation • You receive a detailed quotation specifying the filter type, air quantities, price, delivery time etc. to give you a complete overview of the cost and time schedule of your project.

Production • After having received the order confirmation, we begin manufacturing the filter and equipment at our production facilities in Denmark which ensure the same high quality at all times.

Delivery & Installation • The system is shipped to your location, where it can be assembled and installed under supervision of an experienced supervisor to ensure correct and trouble-free installation.

Commissioning & Training • The experienced supervisor can carry out the commissioning of the system and training of the staff that will be operating the system daily. The system is supplied with detailed instruction manuals for future reference and guidance.

Maintenance & Service • Periodic maintenance and inspection of your system is a necessity to ensure reliable and efficient operation. We can assist you in this, and our service department is available 24/7/365.

SOME DETAILED PROJECT DESCRIPTIONS

Two Efficient Dust Extraction Systems For VELUX

Due to increased production needs and a desire for more energy-efficient solutions, VELUX decided to invest in new dust extraction and replace two old filters with new ones. […]

Dust Extraction System for High Quality Wooden Floors

Located in Denmark, the company produces ultra-high quality wood flooring solutions and other exclusive wood product solutions. Dinesen caters to the high-end market where quality is an absolute selling point. To exist within this market, the company requires the highest standards of […]

Safe, Efficient Dust Extraction Systems

Two dust extraction systems for efficient waste material extraction and air filtration at South American plywood manufacturer […]

Dust Extraction System for Cardboard Manufacturer

The customer was looking for a more cost-efficient waste material handling system, and in close cooperation with our distributor in Finland, PPT Pölynpoistotekniikka Oy, they found a solution with our […]

ATEX Dust Extraction System For Glass Fiber

We recently installed this ATEX dust extraction system for glass fiber dust at one of VELUX’s production sites in Denmark. In regards to the explosion hazard (ATEX), the explosion characteristics of the dust were unknown. Therefore, the dust was […]

Complete Production Line and Air Filtration System for Large Airlaid Manufacturer

Moldow A/S and Dan-Web Machinery A/S, two of the largest international suppliers within their respective fields, have in cooperation just finished the delivery of a complete production and air filtration system for the American Airlaid industry. The customer is one of the world’s largest manufacturers within airlaid – an industry responsible for producing […]

Extraction and filtration system of wood and cement

Air filtration specialist Moldow A/S has supplied three specially-designed, energy efficient dust extraction systems for acoustic panels manufacturer Troldtekt A/S’ 13,000 cubic meters production hall in Denmark. Troldtekt has opened a brand new […]