ROTARY VALVES – ATEX AND NON-ATEX

For use in combination with our dust collectors, Moldow supplies both ATEX and non-ATEX rotary valves. Further to that, two types of ATEX approved rotary valves are offered: RS-EXL without pressure control unit, and RS-EXH with pressure control unit for increased safety in case of explosion.

The Moldow Rotary Valve is universally suitable for continuous pressure-less and non-compressed discharge of material from filters, cyclones, silos or conveyors, and they also function as safety components for isolation of explosions in the filter.

The ATEX rotary valves are type approved for dust explosion class ST 1.

Rotary Valve Design

- The rotary valves are manufactured from steel plates treated with corrosion resistant paint.

- The steel rotor is equipped with 8 hard wearing rubber lamellas to ensure good separation of the inlet and outlet of the rotary valve.

- The inlet and outlet are fitted with flange connection.

- The connection between the rotor and the electric motor is established by coupling and gear.

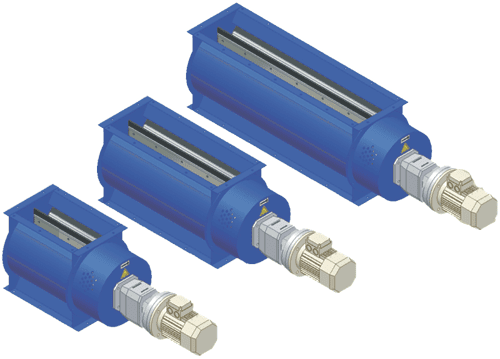

- Both types of rotary valves are manufactured in three different lengths.

VALVE TYPE FOR INCREASED SAFETY

RS-EXH Valve With Pressure Transmitter

Contrary to the RS-EXL valves, the RS-EXH valves are designed with a pressure control unit ensuring that the rotary valve automatically stops in case of an explosion, thereby preventing flames and burning debris from passing through the rotary valve.

A pressure transmitter located on the side of the filter registers the pressure inside the filter. If a significant increase is detected, the control unit automatically shuts down the rotary valve. At the same time, a signal is released that can stop the whole system if connected to the system’s emergency stop device.