BAGHOUSE FILTERS – MODULAR DUST COLLECTORS

Specialist in Energy Efficient, Reliable Baghouse Dust Collectors

Are you looking for a baghouse filter? Moldow specializes in baghouse filters. Moldow’s dust collectors are always designed to be as energy efficient as possible and always comply with current regulations. Our many years of experience in designing baghouse dust collectors has been applied to our products and produced the market’s most durable baghouse dust collectors that assure reliability and a long service life.

The design of the upper part of the baghouse dust collector varies depending on the filter type (MHL, SB or MX), and the hopper, i.e. the bottom part of the filter, can be designed with chain, screw or jet conveyor, rotary valve or bins depending on your needs, space requirements, material type, dust loading and air quantity.

Baghouse Filter & Dust Collector designed for every industry

Moldow provides baghouse filters and dust collectors for a wide range of industries:

- Woodworking industry: With many different design options, our baghouse filters for the woodworking industry ensure reliable extraction and energy-efficient filtration. Depending on space and price requirements, our MHL filters, SB filters and MX filters are available with various material transport and discharge possibilities.

- Paper and cardboard industry: Both separation and filtration units are necessary for extraction and filtration of waste from production processes within the paper and cardboard industries. After separation, Moldow’s MHL, MX or SB filters ensures efficient filtration of the dust-filled air.

- Fiber industries: In production facilities producing or using for instance mineral wool, glass fiber or non-woven material, Moldow’s MHL or MX filter performs secure and reliable extraction and filtration of the fiber-filled air.

Moldow filters can be designed as ATEX baghouse filters for use in potentially explosive atmospheres.

The modular construction of our baghouse filters saves on shipping costs and allows for installation without special tools or equipment at site. The modular design also facilitates easy extension of the filter unit to provide increased air capacity and waste handling should your production capacity increase.

CONTACT FORM

MHL FILTER

Most Popular Baghouse Filter

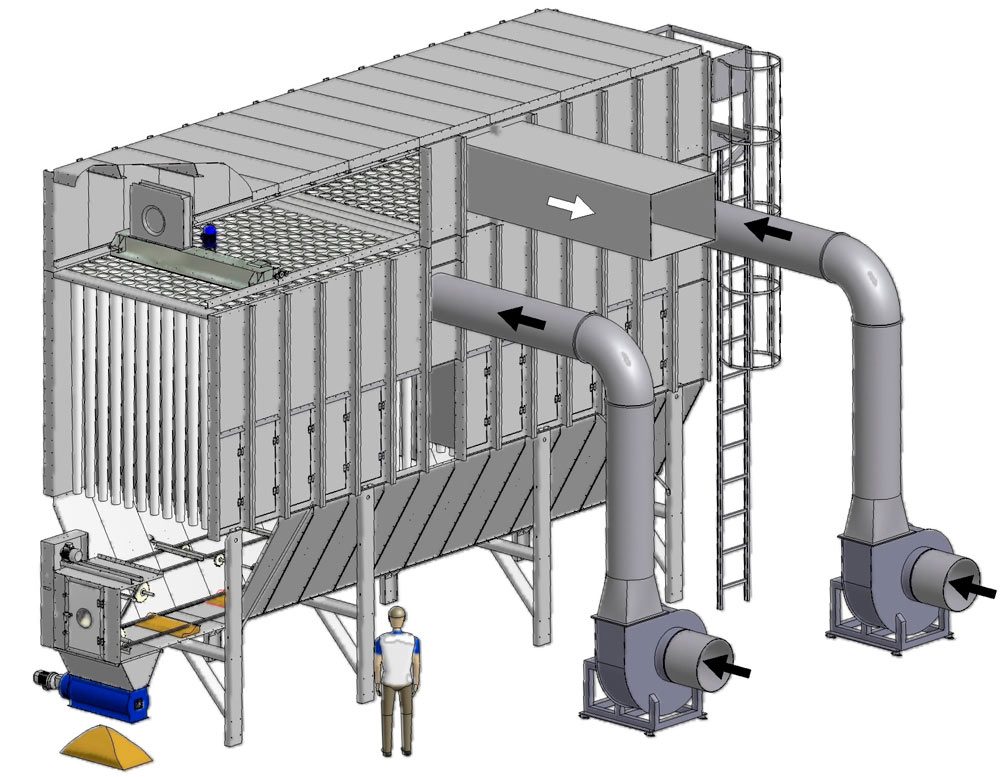

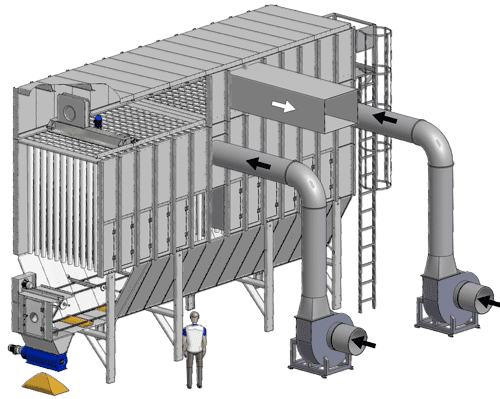

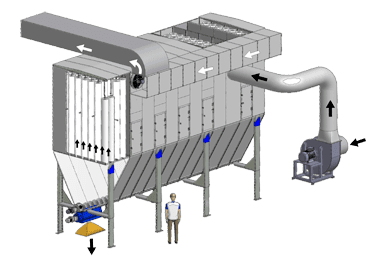

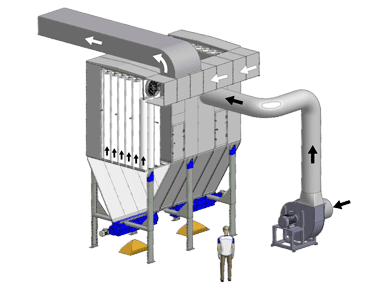

Moldow’s MHL filter, “Moldow High Load”, is a modular baghouse filter designed for air volumes ranging from approx. 20,000 to 250,000 m³/h (11,500 and 150,000 CFM) and continuous operation, 24 hours a day, 7 days a week. It is no doubt our most popular filter system due to the high capacity and easy expansion and adaptation.

The MHL filter can be used in both positive and negative pressure systems, and it can withstand a differential pressure of up to 5,000 Pa (20 in wg).

Our MHL baghouse filter can be delivered with chain conveyor (MHLA), screw conveyor (MHLS) or jet conveyor (MHLJ) depending on the material type, load and air quantities.

One of the clear advantages of the MHL system is the true availability of the complete surface area of each bag for filtering. The filter bags are suspended from the spigot plate, and the outside surface of the bag is used for filtering (with dust settling on the outside). This, together with the conical design of the filter bags which ensures better airflow around the bags, allow for the better utilization of the complete surface area for filtering. Further, the bags are cleaned continuously by use of reverse air. A regeneration cart with a high-pressure fan that sends air from the clean-air chamber back through the filter bags. This is a very efficient way of cleaning the bags, and therefore a filter load up to 180 m³ air per m² filter area per hour (9.8 CFM per sq ft) can be reached, depending on the waste type and volume.

ADVANTAGES OF THE MHL

- High capacity (up to 180 m³/m²/h / ACR up to 9.8:1)

- Positive & negative pressure

- Efficient filtration

- Minimum dust emission

- Continuous operation 24/7

- Efficient high-pressure cleaning

- Special filter bag design

- Low pressure drop (approx. 500 Pa / 2 in wg)

- Modular built, future-proof design

- Up to 80% energy savings with ENSACO

Take a look at this video to learn more about the advantages of a complete Moldow MHL extraction system.

TYPE EXAMPLES

MHL filter for Negative Pressure Systems

MHL filter for Positive Pressure Systems

SB FILTER

The SB filter is an efficient filter suited for positive operation and air volumes from 5,000 to 175,000 m³/h (3,000 to 100,000 CFM) depending on how the filter is constructed and the waste type and volume. The filter is an enclosed, modular bag filter for outdoor installation either on roofs, above waste containers or at ground level outside the building.

The continuous cleaning of the filter bags combined with the efficient waste management ensures high reliability at all times. The filter media is cleaned by a reverse air cleaning system fitted to each module of the filter. This cleaning system can be controlled in a variety of ways depending on the loading and type of material being handled.

The SB dust collector is constructed with either chain conveyor (type SBA), rotary valve(s) (type SBT), screw conveyor (type SBS), or waste bins placed under the filter to collect the waste material (type SBD). The construction is determined based on the material load and type.

For use within the paper and cardboard industry, the filter can also be designed with jet conveyor (SBJ).

The waste is blown by the exhaust air fan to the inlet section of the filter from where the waste material falls to the hopper. Only finest dust particles are carried along with the air stream into the filter bags. The regeneration fans in each section of the filter will periodically run allowing the dust cake inside each filter bag to release and slip down into the base of the filter where it joins the heavier waste. The waste which accumulates in the base of the unit will be removed according to the filter type. The waste removal can be by chain, rotary valve, screw (auger) or into bags/drums. Jet conveying is also available for paper applications.

ADVANTAGES OF THE SB

- Efficient filtration

- Minimum dust emission

- Continuous operation 24/7

- Efficient cleaning system

- Cost-efficient solution

- Modular built

- Flexible design

TYPE EXAMPLES

SBS with Screw Conveyor

SBT with Rotary Valves

MX FILTER

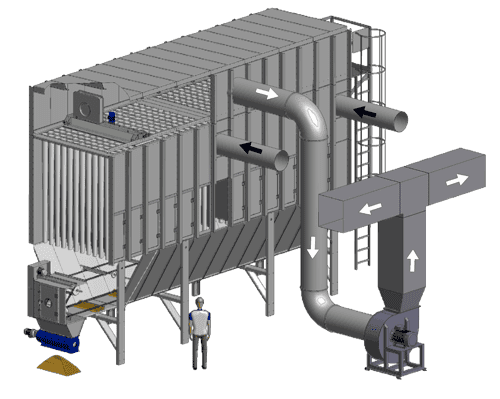

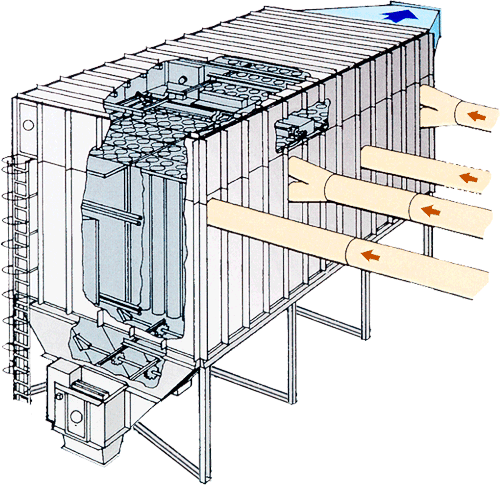

The MX filter is a reliable, modular designed bag filter for continuous operation and intended for both positive and negative pressure systems. The dust collector is used within the fiber industry for production facilities handling e.g. mineral wool, spun glass, cellulose fibers and non-woven fabrics, and within the woodworking, paper, printing and cardboard industries where large amounts of waste material are produced.

It has been designed especially for extraction of large air volumes from 35,000 to 265,000 m³/h (20,000 to 150,000 CFM) and heavy dust loadings. It can withstand a differential pressure of -3,500 Pa (14 in wg).

During operation, the filter bags are cleaned continuously by use of a regeneration carriage with a high-pressure fan. The fan injects air from the clean-air chamber back through the filter. This is a very efficient way of cleaning the bags, and therefore, a filter load of up to 180 m³ air per m² filter area per hour (9.8 CFM per sq ft) can be reached.

The MX filter can be designed with a jet or chain conveyor in the hopper for material transport to the rotary valve.

ADVANTAGES OF THE MX

- Specially designed for heavy dust loadings

- Available for both positive and negative pressure systems

- High filter load (up to 180 m³/m²/h / ACR up to 9.8:1)

- Energy efficient cleaning system

- Minimal pressure loss

- Continuous operation 24/7

TYPE EXAMPLES

MX for negative operation

FT FILTER

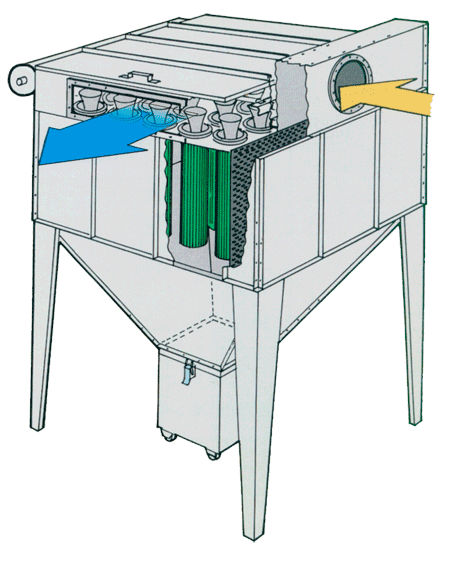

Moldow’s FT filter is a cartridge filter for use within the metal industry. It can be used for extraction of welding dust, metal particles and waste from other similar processes. It is supplied primarily to the Danish market.

The FT filter is supplied for air quantities ranging from 5,000 to 15,000 m³/h, and it can withstand a differential pressure of -3,500 Pa.

It is built in hot-galvanized steel plates and it consist of a separator, a filter cabinet, a regeneration cabinet and a hopper with a dust collector on wheels. It can be located either indoor or outdoor, on the floor or above a silo.

ADVANTAGES OF THE FT

- Efficient filtration

- Minimal maintenance

- Minimal operating costs

TYPE EXAMPLES

FT Cartridge Filter

OLD/LEGACY MOLDOW FILTERS

Replacement items and spare parts for out-of-production Moldow filters

Moldow can support most of our legacy filter products shown here. This includes replacement panels, spares and even extension kits for many models.

Not sure which product you have?

All Moldow filters were delivered with a manufacturer name plates, typically on the non-drive gable. This plate contains the Filter production or serial number. Please provide this number when inquiring about parts or service.

You are also welcome to send detailed pictures of the system, and we will assist in its identification.

TYPES

- DSA Filter

- SA Filter

- ST Filter

- DSJ Filter

- SJ Filter

- STD Filter

- MA Filter

- MTD Filter