FOCUS ON ENERGY EFFICIENT SYSTEMS

Energy Efficiency at the Heart of Every System Design

Globally we meet increasing demands for sustainable and environmentally friendly production. To achieve this, focus must be on the supply of highly optimized production systems, and energy efficiency is one of the key elements to creating an optimized production system.

Moldow painting lines and filter systems have been developed and optimized over the last 50 years with extreme focus on the environment and sustainability. This has produced some of the world’s most energy efficient systems which also meet the most stringent requirements for limiting the escape of pollutants into the environment.

Moldow systems are produced mainly from high quality steel with a high recyclability rate. The systems also provide high production flexibility due to their modular design. Moldow paint lines and dust extraction systems provide some of the lowest Life-Cycle Costs in the industry while assuring a low environmental footprint.

DUST EXTRACTION – REDUCED ENERGY USE

Save Money On Your Dust Extraction

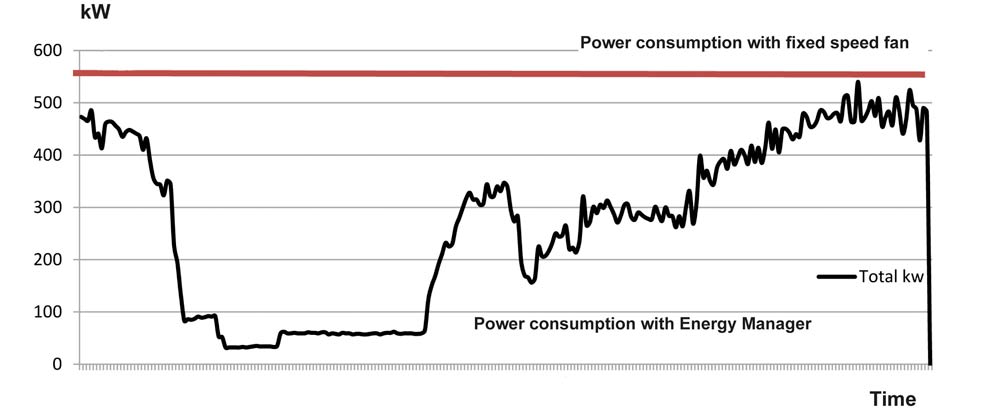

Dust extraction systems and filters generally consume large amounts of energy, but with a system where the components have been designed to minimize pressure drop, interstitial velocity and turbulence, and the airflow is adjusted to the actual demand, large energy savings can be achieved.

Moldow has the necessary know-how to deliver filter systems with the highest filtering efficiency and the lowest energy consumption, which provides both financial and environmental advantages. That is why many of the world’s largest manufacturing companies prefer Moldow’s dust extraction systems.

Moldow filters assure energy savings, high reliability and long service life which makes the investment in a Moldow system cost-effective.

We welcome the opportunity to survey your current system and provide a quotation for an optimization project or a new system. Learn more about our energy saving concepts and control system: ENSACO.