CASE: AUTOMATED PAINT SHOP FOR AUTOMOTIVE PLASTIC PARTS

High quality painting and 25% energy savings at Plasman in Simrishamn, Sweden

High quality painting and 25% energy savings at Plasman in Simrishamn, Sweden

The Swedish company Plastal Sverige AB (now Plasman), a leading manufacturer of plastic parts for commercial and personal vehicles, awarded a contract for the design, installation and commissioning of a painting line to Moldow A/S.

Besides ensuring high quality painting of plastic parts for commercial vehicles, the paint line is intended as a showcase for Plasman’s production efficiency towards their customers.

“For that reason energy awareness and high availability have been key design factors from the beginning of the project, Moldow’s Sales Manager explains.

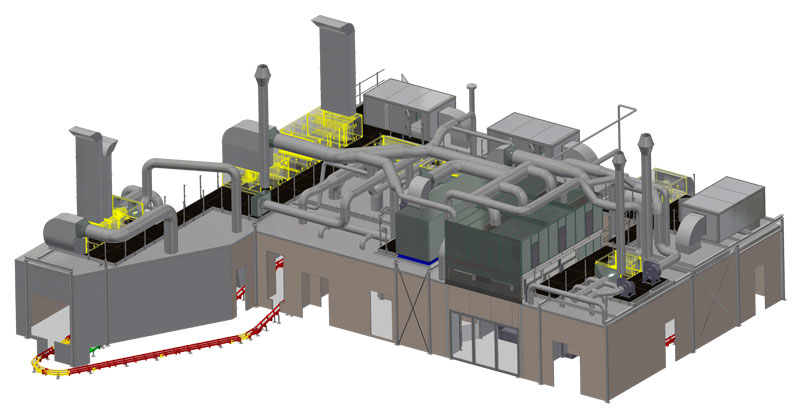

To eliminate contamination and keep the process areas clean and well-presented, a floor mounted chain conveyor transports the goods through the different processes. The automatic Power&Free conveyor transports the parts with up to 10 m/min between the individual process zones utilizing a Stop&Go concept.

The heart of the new line is Moldow’s state of the art spray painting process zone. This zone is equipped with Moldow’s self-manufactured water wall spray booth type HD (Heavy Duty).

– The water wall filtration ensures high yield and high availability due to the HD system, which allows for continuous flocculation of overspray while still operating the spray booth.

Plastic Paint Shop with 25% Energy Savings

The water wall spray booth is fitted with Moldow’s energy saving recirculation concept:

– By recirculating the air flow in the painting area, low air change as well as constant temperature and humidity levels are achieved without compromising the high filtration grade of the Moldow spray booth.

– Our recirculation system ensures a very high paint quality together with significant energy savings while also complying with relevant ATEX requirements. Compared to a traditionally ventilated water wall spray booth, energy savings of up to 25% is achieved.

Beside the direct energy savings, the recirculation concept additionally allows for an optimized treatment of the VOC-loaded exhaust air, as the air flow is kept low and the VOC concentration high. The low air flow and high VOC concentration enable a lower capital investment in VOC abatement systems, and treatment systems such as thermal oxidizers can typically be run auto-thermally thus reducing the operating costs of VOC abatement.

Painting of Automotive Plastic Parts – Satisfied Customer

Beside the spray booth with recirculation, the paint line was delivered with all necessary complementary process zones such as paint kitchen located directly at the spray booth, flash-off zone, cure oven with filtered convection air and final cooling zone. The paint line design furthermore includes the possibility for adding future pretreatment processes by providing space and ventilation.

Plasman is very satisfied with the project and final result as explained by project manager Per Josefsson:

– From the start we knew that we had a tight and critical time schedule. However, thanks to a very professional and focused project management, Moldow has succeeded in meeting our required time schedule and installed and commissioned our new paint line to our full satisfaction. Our impression of the project has been very positive with an excellent cooperation from sales to commissioning including high technical quality and availability. We are particularly pleased with the intuitive and user friendly paint line control system.

“The after-sales service from Moldow deserves praise buy itself as this has been outstanding – quick and effective, Per Josefsson says.

Moldow’s water wall spray booth with recirculation can be used with both suspension conveyor and floor mounted conveyor systems as well as in all types of automatic painting lines where high and uniform paint quality is required.

The project was completed as a semi-turnkey project in cooperation with ABB robot and spray paint specialist RobNor from Sweden, and Moldow was responsible for the final CE marking.

| Customer | Plastal AB |

| Location | Simrishamn, Sweden |

| Item type | Exterior parts for commercial vehicles and other plastic automotive parts |

| Details | The Plastal primer line is designed to achieve high quality painting of plastic parts for commercial vehicles. The line is also intended as a showcase for Plastal’s production efficiency towards their customers, which is why energy awareness and high availability have been key design factors. |