PAINTING LINES FOR WET PAINT AND POWDER COATING

Your Trusted Painting Lines Manufacturer

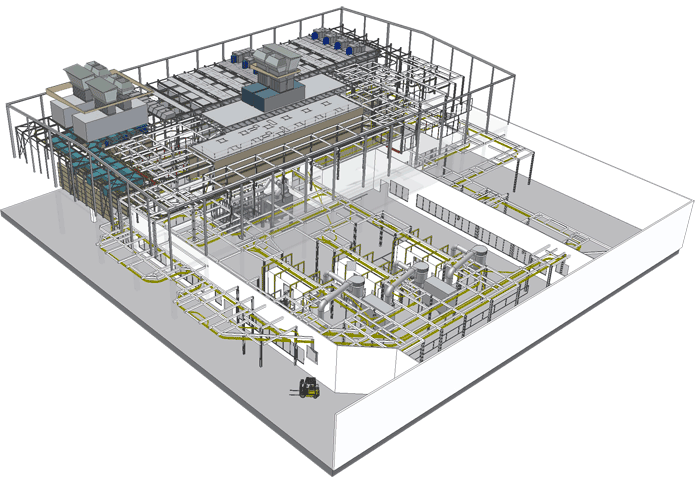

With over 50 years of industry experience, Moldow is one of the leading global suppliers of painting lines for industrial coating of plastic, metal or wood products. We manage every aspect of the process—from design and manufacturing to installation and commissioning—ensuring a seamless, efficient journey from concept to final handover.

Each Moldow Painting Line is engineered for optimal efficiency, reliability, and longevity, and tailored to meet the specific requirements of every project by our expert in-house engineering team. Our ability to customize allows us to deliver solutions ranging from manual to fully automated lines, providing flexibility and precision to suit your needs. Learn more about our offerings and solutions below.

Moldow’s comprehensive wet painting and powder coating lines are delivered with all necessary process zones, including:

- Pretreatment

- Paint application

- Flash-off

- Drying and Curing

- Cooling

- Load and unload

Additionally, we offer integrated options such as control rooms and systems, paint kitchens, sludge management, conveyor systems, and balanced ventilation systems with precise temperature and humidity control.

Customized Painting Lines Tailored to Your Needs

Customer satisfaction is our top priority. Our team of experienced engineers and technicians manage every project from initial concept to final handover, ensuring that your specific requirements are met with precision. This approach guarantees the highest quality standards, seamless delivery, and reliable support throughout the process.

Since a turnkey painting line often includes equipment beyond our product range, we partner with leading suppliers of robots, spray equipment, and sludge management systems. This collaboration ensures the complete painting line meets the highest quality and performance standards.

Companies that benefit from having a Moldow painting line includes manufactures of:

CONTACT FORM

EXAMPLES OF SUPPLIED PAINTING LINES – PROJECT DETAILS

Discover how our solutions have enhanced the quality of our customers’ painting and coating processes, with these examples showcasing a few of the successful lines that we have designed for valued customers.

Market-leading Low Scrap Painting Line for Automotive Parts

The complete plant layout for this automotive plastic painting line was designed in close cooperation between Moldow and Farplas to optimize workflow and minimize footprint […]

Painting Line for Tier 1 Automotive Parts

The plastic painting line that we have supplied for Polyplastics in India is used to paint the front grills and other moulded plastic parts for Suzuki, Renault and […]

Automated Plastic Painting Line in Sweden

High quality painting of automotive plastic parts and 25% energy savings at Plastal in Simrishamn, Sweden. In early 2018, the Swedish company Plastal AB, […]

State-of-the-Art Powder Coating with Advanced Robot Application

High quality powder coating with frequent color changes at Bramidan A/S’ new painting line in Denmark. As part of a larger investment plan, they decided to replace their existing, manual wet paint line with a […]

Painting Line for Plastic Automotive Trim Parts

High quality plastic painting line supplied for automotive trim part is designed to minimize contamination between the individual zones to achieve the necessary high-end product quality […]

Manual Painting Line For 38 M Long Wind Turbine Towers

Moldow has delivered a painting line including sand blasting booth and two paint cabins for Titan Wind Energy in Esbjerg, Denmark – a company that produces […]

Highly Flexible Powder Coating Line for Steel and Aluminium Items

This automated painting line for powder coating of signs and boards was designed by Moldow to meet the requirements of exceptional flexibility. This was a special […]

Two-leveled Powder Coating Line for Forklifts

With the ambition of reaching the overall environmental, quality and capacity targets of Toyota Material Handling Europe, Moldow supplied this automated powder coating line […]

Paint Shop for Automotive Plastic Parts

Paint shop design to high-end painting of plastic parts – Moldow has designed this painting lige for Plasman in Gothenburg […]

Maximum Energy Efficiency and Minimal Carbon Footprint

– For Your Benefit and a Better Environment

Energy efficiency and sustainability are at the core of every plant we design. For over 50 years, we’ve integrated energy-saving solutions into our systems, ensuring that each facility operates efficiently and responsibly.

Our expertise allows us to optimize and customize each layout to meet your specific needs, focusing on maximizing efficiency, minimizing operating costs, and leveraging advanced technology—all while reducing the overall environmental footprint.

Your Needs are the Foundation of Every Project

We start with your requirements and combine them with our expertise to deliver the ideal painting line solution for your business.

With over 50 years of experience and a skilled team of engineers and project managers, we provide turnkey installations tailored to meet the specific needs of your industry and company.

We support you throughout every stage of the project—from the initial briefing to final handover and ongoing after-sales services—ensuring a seamless, successful outcome and a solution that truly satisfies.

Explore our previous painting line projects to see how we’ve delivered the perfect solutions for our customers.

PAINTING LINE DESIGN ACCORDING TO SPECIFIC NEEDS

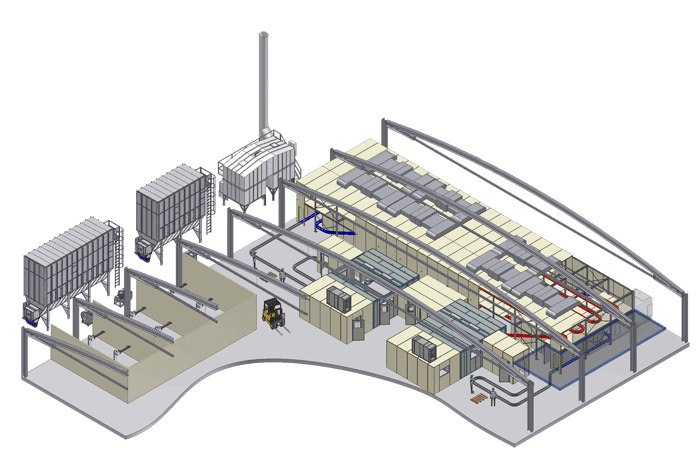

The design of a painting line can range from being fully manual with both the transportation from one process to another and the paint application being handled manually to a semiautomatic or full automatic painting line, where the transportation and/or application is automated.

Manual Painting Lines

A manual painting line is suitable when flexibility is crucial, e.g. when painting large, complex items or items of varying sizes and shapes. With many color changes, a manual paint application can also be the best solution.

The painting lines are designed with the required boxes and cabines for cleaning, pre-treatment, application and curing, and all processes are separated and ventilated according to needs.

Automatic Painting Lines

If there is a need for a painting line with large capacity, a full-automatic painting line is the best way to ensure an efficient and reliable painting process. In other situations, a semi-automatic line with manual handling of some of the processes can be the best solution.

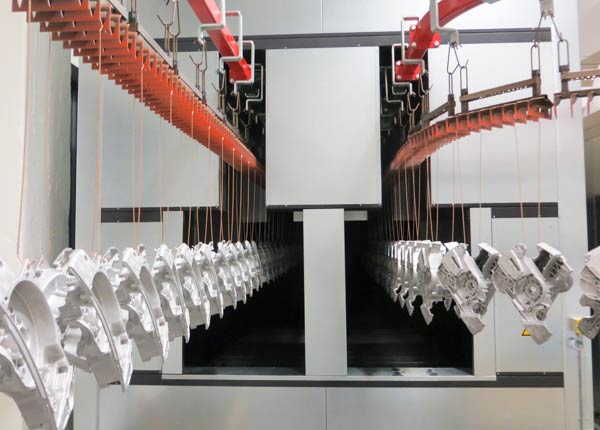

In a fully automatic painting plant, the items are transported automatically from one process zone to another either on overhead conveyor, floor-mounted conveyor, power and free-conveyor or roller conveyor, and the paint application is performed by use of robots.

The complexity of an automatic painting line varies a lot depending on item type, capacity needs and surface treatment. Moldow’s many years of experience makes us specialists in designing these complex painting lines, where the design and composition of the different process zones ensure a final result that meets expectations.

Moldow designs and supplies a range of industrial painting lines for both wet paint and powder coating systems.

Each line is customized to suit the material being painted – whether metal, plastic, or wood – and the specific production requirements and layout of each customer.

The possible solutions includes manual, semi-automatic, and fully automated lines with advanced processes, air-handling, drying and curing, and auxiliary systems to ensure top-quality finishes and high energy efficiency.

Moldow’s painting lines are designed to handle and treat a variety of product types and materials, including:

- Metal components – for industrial machinery, consumer goods and architectural parts.

- Plastic parts – especially automotive interiors & exterior parts but also consumer goods and electronics.

- Wood – for furniture, panels and decorative items.

Each line is engineered with the correct pre-treatment, temperature control, and air balance to ensure optimal adhesion and finish quality for each material type.

Both wet paint and powder coating lines are used to apply protective and decorative coatings, but they differ in technology and performance:

- Wet paint lines use liquid paints and are suitable for materials like plastic or wood, or when special finishes (metallic, gloss, etc.) are required.

- Powder coating lines use dry powder that is electrostatically applied and cured, offering superior durability and environmental performance — ideal for metal products.

Moldow provides both types and can advise on which process best fits your product type, throughput, and finish requirements.

Powder coating and wet painting are both popular methods for protecting and finishing metal parts, but they differ in application, durability, and environmental impact.

| Aspect | Powder Coating | Wet Painting |

| Application method | Uses an electrostatic process to apply dry powder that is then cured in an oven. | Applies liquid paint using spray guns or dipping, followed by air or heat drying. |

| Durability | Forms a hard, uniform surface that resists corrosion, chipping, and UV exposure. Ideal for heavy-duty industrial use. | More prone to scratching, fading, and corrosion over time. Often used for decorative finishes or low-stress environments. |

| Environmental impact | Eco-friendly – no solvents or VOC emissions; overspray can be recycled. | Less sustainable – contains solvents that release VOCs during drying. |

| Finish quality | Provides a smooth, even coat with excellent color retention and gloss consistency. | May show drips, uneven thickness, or orange peel if not applied carefully. |

| Cost-effectiveness | Lower long-term cost due to material reuse and reduced maintenance. | Lower initial cost, but typically higher lifetime maintenance. |

In summary, powder coating lines offer a more durable, consistent, and environmentally friendly finish compared to wet painting — making them the preferred choice for industrial and metal fabrication applications. Moldow’s systems are engineered to maximize these advantages with energy-efficient ovens, precise air management, and advanced automation.

Yes. While Moldow primarily supplies painting lines to customers across Europe, we also deliver specialized systems worldwide, particularly for the automotive industry.

Moldow has unique expertise in painting lines for automotive plastic components, such as bumpers and trim parts. These projects require highly precise air handling, temperature control, and contamination management – areas in which Moldow has decades of proven experience. Because few suppliers globally can match this level of technical capability, Moldow’s automotive plastic painting lines are exported to clients worldwide, supported by our engineering and service teams to ensure reliable performance and long-term operation.

Moldow’s powder coating lines are primarily supplied to European production companies. If you are located outside of Europe and are interested in a Moldow powder coating line, please contact our sales team to discuss your project — we will assess feasibility and provide guidance on how we can best support your needs.

Yes. All Moldow painting lines are built with energy-saving features such as high quality panels, insulation of needed walls and pipes to ensure heat conservation and efficient components design. In addition, extra energy efficient systems and features can be included such as heat recovery systems, controlled air recirculation, and efficient exhaust filtration. These reduce both energy costs and environmental impact, while maintaining strict process stability.

OTHER PRODUCTS

Moldow designs, manufactures and supplies complete painting lines for wet paint and powder coating of metal, plastic and wooden items. This means that in our delivery, a wide range of services, systems and products are included including among others:

- Pretreatment booths

- Paint booths

- Flash-off zones

- Drying and curing ovens

- Ventilation systems

- Loading/unloading systems

- Paint kitchens

- Sludge handling systems

- Control systems

Given that a turnkey painting system includes equipment outside Moldow’s range of products, cooperation agreements with the best suppliers of e.g. robots, spray equipment and conveyor systems ensures the high quality of the whole painting line.