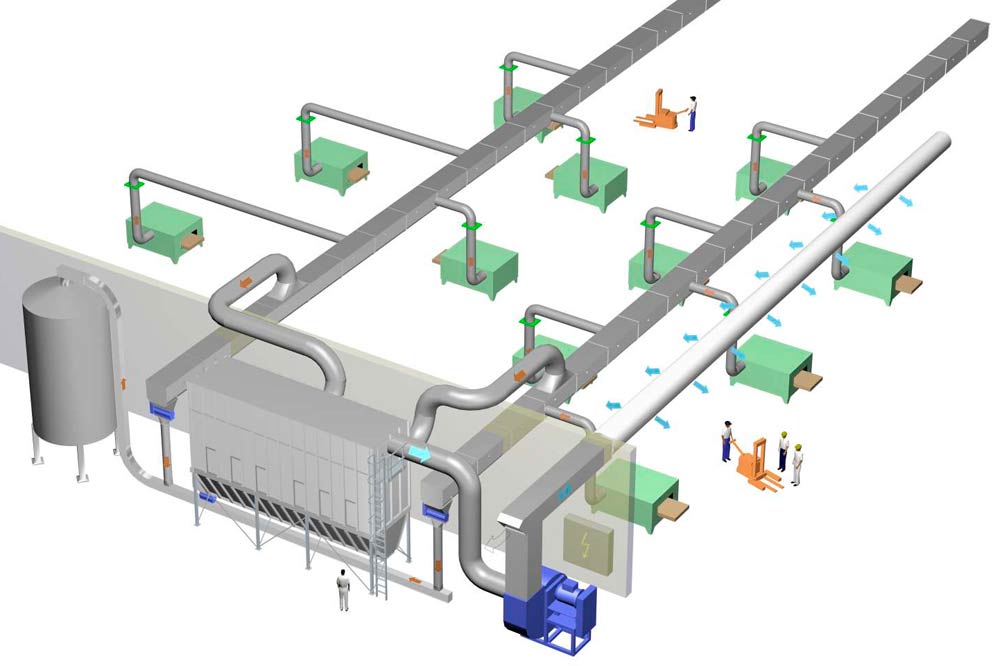

TRANSFLOW SYSTEM

Transflow Separation Ducting System

The Transflow system can be a great advantage for production facilities within the woodworking industry with large amounts of extraction material as it allows for handling of large dust loads and flexible machinery placement and connection.

As the waste material enters the Transflow, the airspeed is greatly reduced due to the plenum design. This forces all but the finest particles to fall out of the airstream and into the base of the Transflow system where a chain conveyor transports it to a rotary valve situated at the end of the unit. After passing through the rotary valve, the material is transported in a dilute pneumatic conveying system or alternatively to a chain conveyor system and further to a waste silo or container. The light air-borne dust, which remains in the airstream, is passed on to a traditional bag filter system.

The Transflow system is a Plenum type separator with a maximum length of 70 meters. Machines can be connected directly to inlets along the full length of the unit eliminating the need for a branched type duct system. This allows machines to move with a minimum need for new ducts.

CONCEPT

ADVANTAGES

- Extraction of large quantities of dust and chips

- Constant pressure: air demand/energy use follows active machines

- High flexibility: machines can be moved without rebalancing system

- Cheaper, more efficient fans as waste is removed from the air

- Higher load – smaller filter

- Modular construction: can be extended as production grows