INTRODUCING ENSACO®: REVOLUTIONIZING ENERGY EFFICIENCY

Energy Saving Control System for Dust Extraction Systems

ENSACO® represents a cutting-edge advancement in energy management systems, building upon the proven success of Moldow’s Energy Manager System while incorporating innovative energy-saving concepts.

ENSACO® represents a cutting-edge advancement in energy management systems, building upon the proven success of Moldow’s Energy Manager System while incorporating innovative energy-saving concepts.

In a typical woodworking factory, a staggering 35% of energy consumption is attributed to dust extraction. With the current and needed focus on sustainability and CO2 reductions, optimizing and reducing the energy usage in extraction systems becomes paramount.

Moldow is proud to present ENSACO®, a groundbreaking solution designed to reduce energy consumption by up to 80%.

ENSACO® is based on 25 years of development and knowhow in extraction systems and energy optimizations and 45.000 hours of testing. This ensures a robust and reliable solution for your company.

Beyond a mere control system, ENSACO® offers an initial assessment and a comprehensive overview of potential savings through the rebuild and improvements of your extraction equipment.

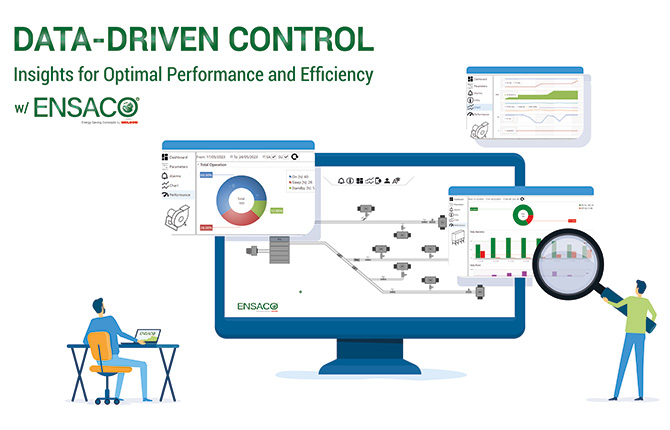

Compared to its predecessor, the Energy Manager control system, ENSACO® has a more user-friendly interface. With intuitive navigation and a clear overview tailored to your factory layout, ENSACO® sets a new standard for ease of use in energy management systems. Optimize your operations, reduce costs, and embrace sustainable practices with ENSACO®.

BASED ON 25 YEARS OF KNOW-HOW AND EXPERIENCE

COMPATIBLE WITH ALL TYPES OF EXTRACTION SYSTEMS

OPTIMIZED EQUIPMENT PERFORMANCE

STATE-OF-THE-ART

CONTROL SYSTEM

User-friendly, intuitive control system

for easy system overview and control

+ documented energy consumption and savings

INITIAL SYSTEM SURVEY AND RECOMMENDATIONS

With our survey and advise you get an overview of the possibilities and costs of rebuilding your system to achieve large energy savings

ENERGY SAVINGS UP TO 80%

Save up to 80% on the energy consumption of your dust extraction system with ENSACO® control system, Moldow range of filters, fans and other equipment.

The ENSACO control system itself typically delivers 40-60% savings.

Initial System Survey and Report

A thorough survey of your existing extraction system is a key part of the ENSACO® process and forms the foundation for the entire project.

An experienced sales engineer performs the survey to understand your unique setup and identify possibilities and limitations. Following the survey, you will receive a detailed report that includes:

A documented business case

Identified improvement opportunities

Potential energy and cost savings

A payback calculation and savings scenario

This gives you a clear overview of both costs and benefits, enabling you to choose the solution that best fits your production and budget.

REQUEST A FREE SURVEY

How Does ENSACO® Work?

ENSACO® continuously monitors and automatically adjusts dust extraction levels based on real-time machine activity — ensuring energy is used only when and where it’s needed. No more, no less. The result?

✅ Reduced power consumption

✅ Lower operating costs

✅ Improved environmental footprint

✅ Seamless, automated control

In this video, you can see how ENSACO® communicates with the production and entire extraction setup — including I/O stations, production machines, transmitters, sensors, and the central dust-extraction control system — to deliver precise and efficient airflow management.

ENSACO® Energy Saving Examples

Replacement of an old filter to a Moldow filter and fans, replacement of part of the ductwork and installation of energy saving control system:

PROJECT EXAMPLE 1

Before changes 104 kW

After replacements 21 kW

After control system 15 kW

Total Savings 80 %

PROJECT EXAMPLE 2

Before changes 110.2 kW

After replacements 38.3 kW

After control system 25.6 kW

Total Savings 72 %

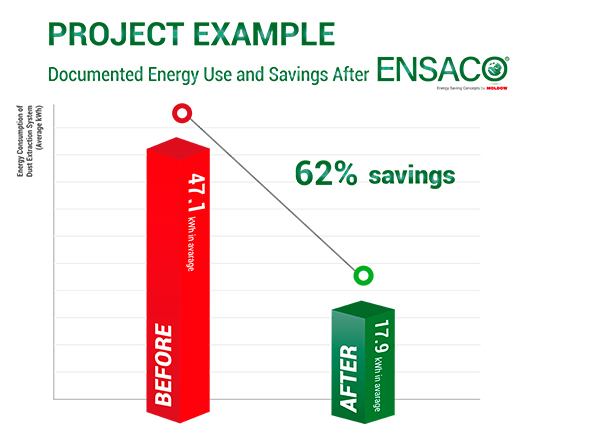

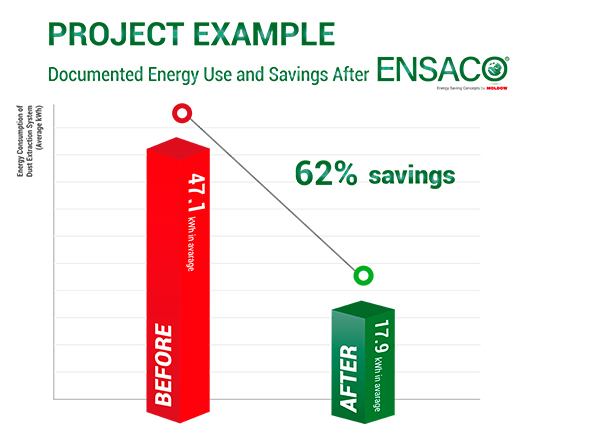

Installation of energy saving control system alone

PROJECT EXAMPLE 3

Before changes 150 kWh in avarage

After control system 68 kWh in avarage

Total Savings 55 %

PROJECT EXAMPLE 4

Before changes 95 kWh in avarage

After control system 37 kWh in avarage

Total Savings 63 %

CONTACT FORM

Valuable Data Insights

In addition to delivering significant energy savings for a factory’s dust extraction system, ENSACO offers valuable data for improved production efficiency and a more proactive approach to maintenance and troubleshooting.

With ENSACO®, you gain insights into:

➡️ Machine Operation Times:

Track exactly how many hours each machine operates and at what times throughout the day. This enables optimizations, precise scheduling and optimal maintenance.

➡️ Error and Warning Analysis:

Access a detailed log of errors or warnings over any selected period, including their specific causes, for proactive troubleshooting and reduction of downtime.

➡️ Event Timeline:

Review a clear, comprehensive timeline of events, so you always know exactly what occurred and when.

➡️ Component-Level Energy Consumption:

Monitor the energy usage of each component of the dust extraction system, allowing targeted, documented improvements.

This rich data translates seamlessly into actionable insights, enabling improved production efficiency, reduced energy costs, and a more proactive approach to maintenance and troubleshooting.

With ENSACO®, factories can not only save energy but also enhance their overall operational performance.

ENSACO® CONTROL SYSTEM

Born from 25 years of unparalleled experience, collaboration, and dialogue between Moldow and industry professionals worldwide, the ENSACO® control system is an enhanced iteration of the Moldow Energy Manager System.

ENSACO® is engineered to deliver energy savings through meticulous monitoring of machines and extraction points, dynamically adjusting extraction volumes based on actual needs. Its demand-driven operation not only ensures minimal energy consumption but also extends the lifespan of filters and other extraction equipment.

Our focus on reliability, user-friendliness, future-proofing, optimized performance, flexibility, and energy savings has shaped every aspect of ENSACO®’s development.

Available both as a stand-alone unit for seamless integration with existing systems and as an integral part of a complete Moldow dust extraction system, ENSACO® caters to positive or negative pressure systems with equal finesse.

Experience the ease of monitoring, adjustments, and settings through the intuitive ENSACO® touchscreen or via network connection on a computer.

ENSACO® ENERGY CONCEPTS

Previously, we often experienced that our customers wished to purchase an energy control system but could achieve significantly larger energy savings by also replacing parts of their extraction equipment at the same time with multiple other advantages. That is why we added energy concepts to ENSACO®.

If the ENSACO® control system is supplied together with the Moldow cutting-edge filters, fans and other equipment as well as installation concepts, you stand to gain remarkable energy savings of up to 80%, outshining conventional systems.

Drawing from over 25 years of expertise in optimizing extraction system energy, we provide a comprehensive initial survey of your current setup. Our team then guides you on strategic rebuilds that promise significant energy savings, often with an impressively short payback time.

ENSACO® — where advanced technology meets efficiency, setting new standards for energy control systems.