ROTARY MATERIAL SEPARATOR – DANSEP UNIT

Effcient material separation within paper, carton and corrugated cardboard

Effcient material separation within paper, carton and corrugated cardboard

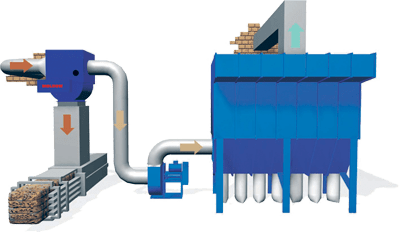

Moldow offers the highly trusted DanSep rotary airlock separator for energy efficient, effective and compact waste and trim separation.

The DanSep material separator unit can be used as the main separation component in your extraction system, and it can be placed directly over balers, containers and compactors of all kinds and before dust extraction systems.

DanSeps separator can separate most paper and polymer materials in thicknesses from films to corrugated cardboard, and is an essential production component for many manufacturers of e.g. paper, coffee filters, corrugated cardboard boxes and much more.

Advanced Material Separation Technology

The DanSep construction has been developed and optimized through many years ensuring the very best solution and a durable construction.

The DanSep construction has been developed and optimized through many years ensuring the very best solution and a durable construction.

The DanSeps comprise a separator housing, separation screen, rotor and drive unit plus safety components.

Based on market need, we have developed a special HP model for which can withstand a pressure of -6.000 Pa. Standard models are designed for -2.500 Pa.

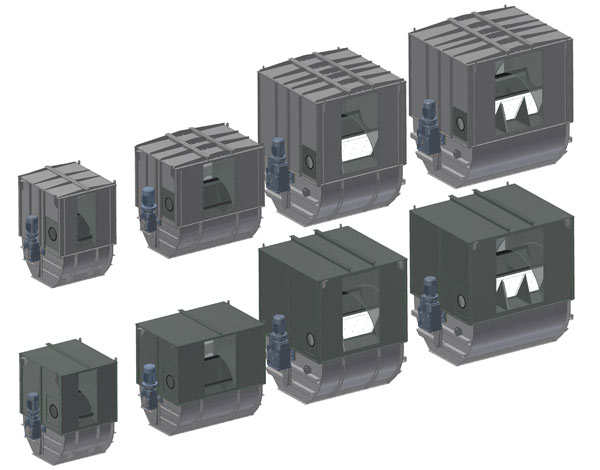

DANSEP SIZES

Design for Every Capacity Requirement

The Moldow material separator comes in five different types and in a HP (High Pressure) model and standard model:

- DanSep 6 – up to 8,000 m³/h (4700 CFM)

- DanSep 22 – up to 22,000 m³/h (13,000 CFM)

- DanSep 35 – up to 35,000 m³/h (20,600 CFM)

- DanSep 50 – up to 50,000 m³/h (29,500 CFM)

- DanSep 60 – up to 60,000 m³/h (35,300 CFM)

CONCEPT

ADVANTAGES

- High reliability

- Efficient separation

- Low pressure-loss and pressure-less separation

- Simple and reliable technology that reduces your operation cost

- Improved working environment

- Compact unit with large separation capacity

CONTACT FORM