MOLDOW AWARDED CONTRACT TO SUPPLY AXELENT’S NEW POWDER COATING LINE

Moldow will be supplying a powder coating line for one of the world’s leading companies in safety solutions, Axelent.

– We are very pleased to have been awarded this contract by Axelent for the design and installation of their new, large powder coating line. Axelent’s choice of us as the supplier is proof that our solutions are among the absolute best and meet the current requirements for technology and energy efficiency, while at the same time being price competitive, Managing Director at Moldow, K. Preben Hansen, says.

– We chose Moldow as the main supplier primarily based on the experience as a whole. Moldow has listened to what we at Axelent wanted to achieve, and they were quickly able to come up with a plant solution based on our requirement specifications. Moldow has been very professional and able to meet our expectations to engineering, quality, delivery time, conditions and price in a very satisfactory way, Carl-Johan Magnusson from Axelent says.

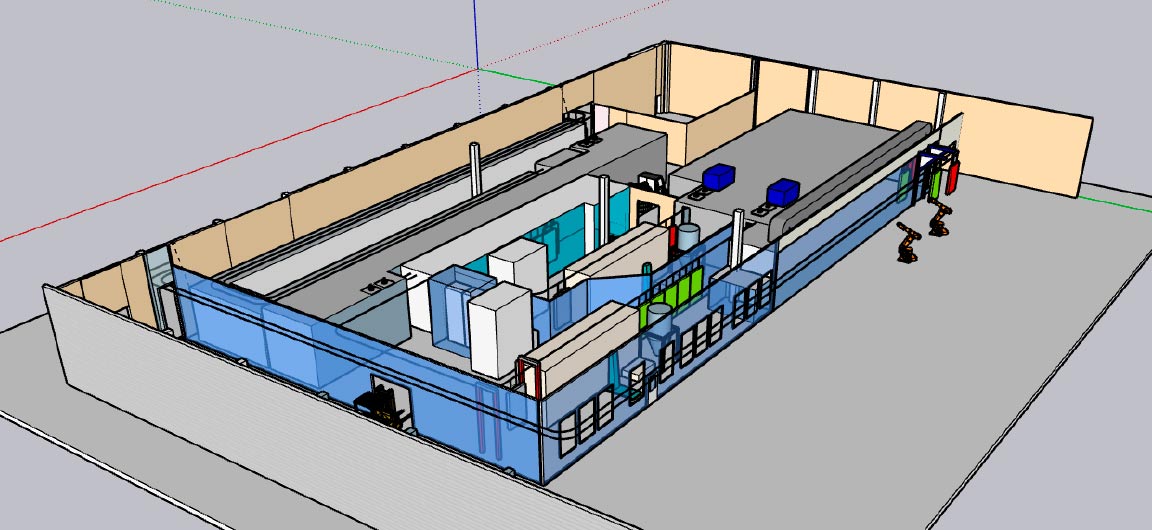

The new powder coating line will be built at the Axelent headquarters and production facilities in Hillerstorp, Sweden. The powder coating line is for coating of Axelent’s well-know products in steel which among others include their mesh wall safety systems for protection and partitioning systems for industry, warehouses and construction.

– I don’t want to reveal the order amount, but we are talking about one of the larger powder coating lines that we have supplied, K. Preben Hansen says.

Powder Coating Line with Focus on Sustainable Solutions

Energy efficiency and sustainability are crucial to how Moldow design their painting lines and have been so for many years. They also play an important role in this project.

– A large part of the investment is to build a line that is as energy efficient as possible. For us it is important that the line is designed so the process can be carried out in a sustainable way and with the lowest environmental footprint possible – now and in the future, Carl-Johan Magnusson says.

In one area where this in put into practice is how the ovens are heated. Normally, the drying and curing ovens are heated with gas or electricity – with gas being the most common solution as it is the cheapest to install.

– Axelent has chosen a solution with electrical heating of the ovens which is a more expensive but sustainable solution. Futher to that, recirculation and reuse of the heat will be included to make the line as energy optimized as possible, Technical Manager from Moldow, Lars Holm, explains.

Designing and supplying the more sustainable solution is not something new for Moldow.

– For more than 40 years, we have supplied both solutions to our customers based on their needs and focus. The wish for a greener, sustainable profile and the expectations to the gas and electricity prices means that in many cases electricity is the preferred solution and expected to be a cheaper solution in the long run despite the larger investment cost, Lars Holm says.

– However, it is important keep in mind that the heating solution does not (alone) make the oven more or less energy efficient. Our ovens are generally speaking highly efficient despite the heating form thanks to recirculation, optimal heating distribution and heat reuse. Electrical heating generally makes them more green and sustainable, Lars Holm says.

From Sub-supplier to Painting In-house

Today, Axelent’s products are painted by a local sub-supplier. With the new line, part of the products will be painting in-house instead.

– At Axelent, we have always used a local sub-supplier for painting of our products. Now we have chosen to invest in our own coating line, primarily to solve the logistical challenges that we have and will arise in the future due to the expected increased volume, Carl-Johan Magnusson from Axelent says.

– We have used our sub-supplier since Axelent was founded, so our continued partnership and cooperation will also in the future will be very important for our growth.

– The investment in a powder coating line is something new for our company and a challenge for us, but we are confident and convinced that the result will be good with Moldow as the main supplier, Carl-Johan Magnusson from Axelent says.

About Axelent:

Over three decades, Axelent has grown to become one of the world’s leading companies in safety solutions for people in manufacturing and warehousing environments. The company’s headquaters are in Hillerstorp, Sweden, where all products are also developed and produced.

Axelent employs more than 300 people around the globe and has 10 subsidiaries in Europe, Asia, Australia and USA, but also sell their products through approx. 30 agents worldwide.

Your needs as our customer are the foundation for every project

Based on your needs combined with our know-how, we find the right painting line solution for you.

With more than 50 years of experience and a competent staff of engineers and project managers, we are capable of supplying turnkey installations to comply with the specific requirements of each industry and your company.

We got your back all the way through a project – from the first brief to the final hand-over to the after-sales services. This will ensure a successful and satisfying project phase and solution.

Have a look at other painting line projects where we have ensured just the right solution for our customers.

Maximum Energy optimizations and minimal carbon footprint – to benefit you and our environment

Energy optimizations and sustainability is crucial and play a fundamental role in every plant design.

For us, this is not something new. For more than 50 years, we have incorporated energy saving solutions in our designs.

We know how to optimized and customize each layout and design to fit your requirements in terms of efficiency, running costs, technology and footprint.